Efficient 500KG Apple Drying Process: How a Heat Pump Dryer Delivers Quality & Savings

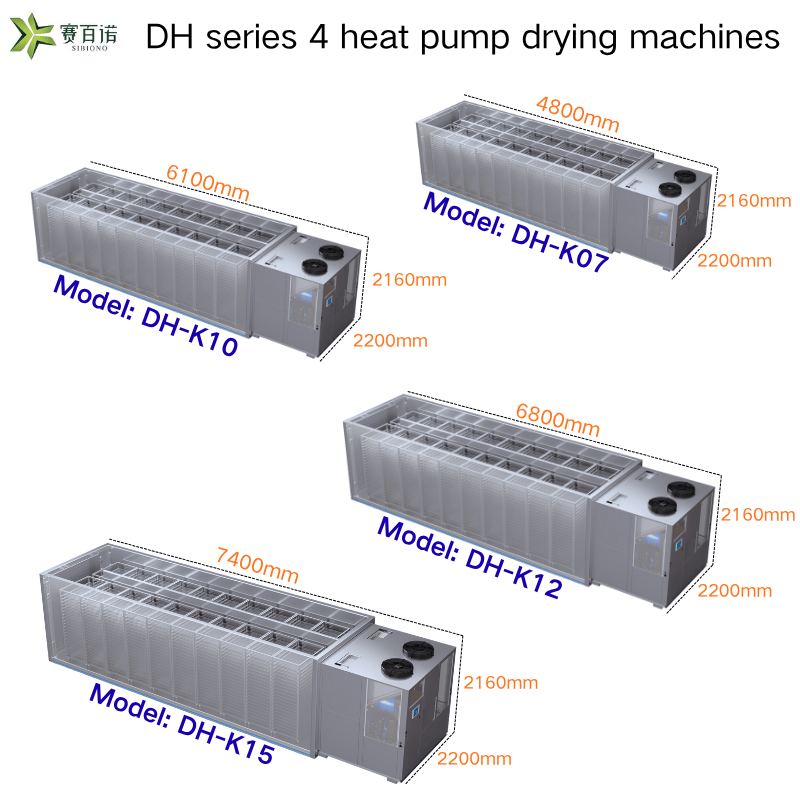

For commercial dried fruit producers, mastering the drying process for medium-scale batches like 500kg of apple slices is key to profitability and quality control. While many types of dehydrator equipment exist, the heat pump dryer has become the industry leader for efficiency and product quality. This article provides a detailed, step-by-step guide to the optimal drying工艺 (process) for 500kg of apple slices using this advanced technology.

Why a Heat Pump Dryer is the Ideal Choice for 500kg Batches

When processing 500kg of apples, the limitations of a small fruit dryer become apparent, and the high fuel costs of traditional methods eat into profits. A heat pump dryer offers a perfect balance for this scale:

-

Unmatched Energy Efficiency: By recycling heat from the exhaust air, it uses up to 60% less energy than conventional electric heating dehydrator systems.

-

Premium Product Quality: Low-temperature drying (40-65°C) preserves the apple’s natural color, nutrients, and shape, preventing the hard shell and burnt taste that cheaper methods can cause.

-

Precise Control: Automated control over temperature and humidity ensures every batch is consistent, which is crucial for building a trusted brand.

The Step-by-Step Drying Process for 500kg of Apple Slices

Step 1: Preparation and Slicing

Before the apples even enter the apple dryer, proper preparation is vital.

-

Washing & Sorting: Fresh apples are thoroughly washed to remove dirt and pesticides. Damaged or rotten fruits are discarded.

-

Peeling & Coring: Depending on the final product requirement (e.g., for apple chips or dried segments), apples may be peeled and cored.

-

Uniform Slicing: Apples are sliced to a consistent thickness of 5-8mm. This is a critical step; uneven slices will dry at different rates, resulting in a batch that is either too moist or over-dried.

Step 2: Loading the Industrial Heat Pump Dryer

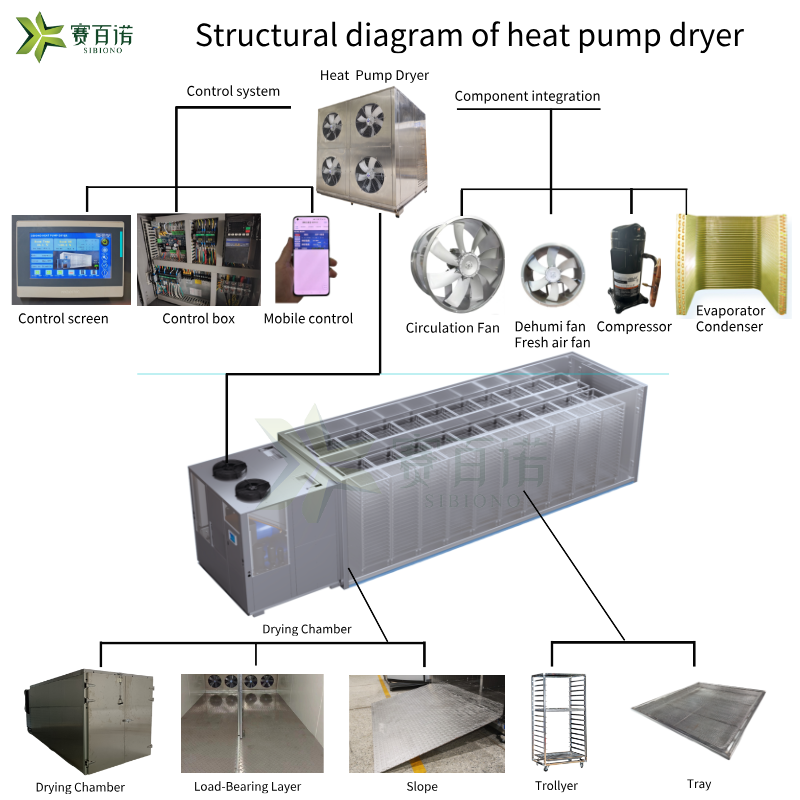

The sliced apples are evenly spread onto stainless steel trays. These trays are then loaded onto trolleys that roll directly into the drying chamber of the heat pump dryer. Proper air circulation is key, so trays must not be overloaded.

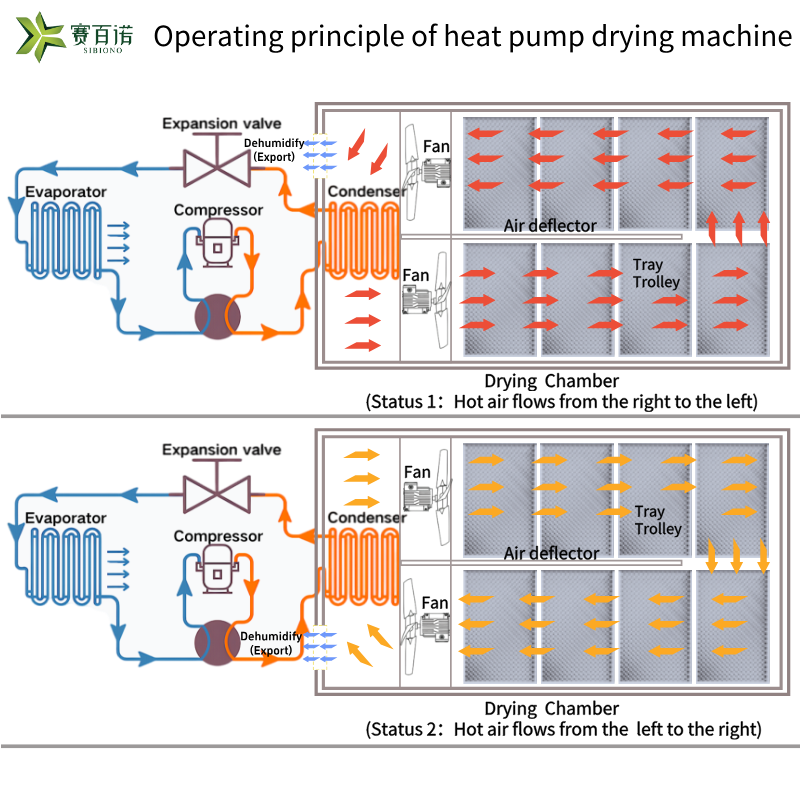

Step 3: The Drying Cycle with the Heat Pump System

This is where the heat pump drying machine demonstrates its superiority. The operator sets the optimal parameters:

-

Initial High-Temp Phase (1-2 hours): Temperature is set to ~65°C (149°F) to remove surface moisture quickly without cooking the apple.

-

Main Low-Temp Phase (6-8 hours): The temperature is reduced to 55-60°C (131-140°F) to gently remove internal moisture. The system’s dehumidifier continuously removes moist air, while the heat pump recycles the thermal energy.

-

Final Conditioning Phase (1 hour): Temperature is lowered further to ensure the moisture content is evenly distributed and reduced to the target level (typically below 10%).

Total Drying Time: Approximately 8-11 hours for a 500kg batch.

Step 4: Cooling and Packaging

Once the cycle is complete, the dried apple slices are not immediately packaged.

-

Cooling: The slices are cooled to room temperature. This step prevents condensation from forming inside the packaging, which would lead to spoilage.

-

Quality Check & Packaging: The final product is checked for quality and consistency before being packaged in airtight bags or containers for shelf stability.

Advantages Over Traditional Dehydrator Methods

Compared to a standard cabinet dehydrator or a fossil-fuel-fired fruit dryer, a heat pump system provides:

-

Lower Operational Costs: Significant reduction in electricity consumption.

-

Better Color Retention: The gentle heat prevents browning, resulting in a more appealing golden-yellow color.

-

Enhanced Food Safety: Controlled humidity inhibits microbial growth during the drying process.

-

“Set and Forget” Automation: Once programmed, the system requires minimal supervision.

Conclusion: A Smart Investment for Growth

For a business processing 500kg of apple slices, investing in a specialized apple dryer that uses heat pump technology is a strategic move toward growth. It ensures a high-quality product that commands a better market price while significantly reducing energy overhead. By following this optimized process, producers can achieve a superior dried apple product efficiently and consistently, building a strong reputation in the competitive dried fruit market.