Product descriptions from the supplier

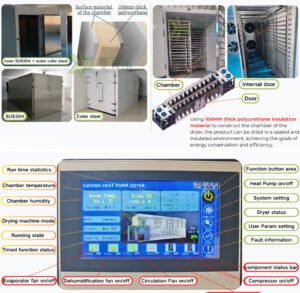

1. What is SIBIONO Heat Pump Dryer?

SlBlONO Heat Pump Dryer is an advanced solution for food and industrial drying applications.

- Heat pump technology reduces electricity costs to just 25% compared to conventional dryers.

- Fully electric-driven with no open flame, ensuring safe operation and zero CO₂, emissions.

- Touch-screen + mobile app connectivity for precise control of temperature, humidity, and drying time.

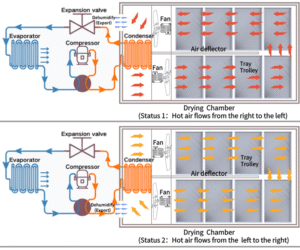

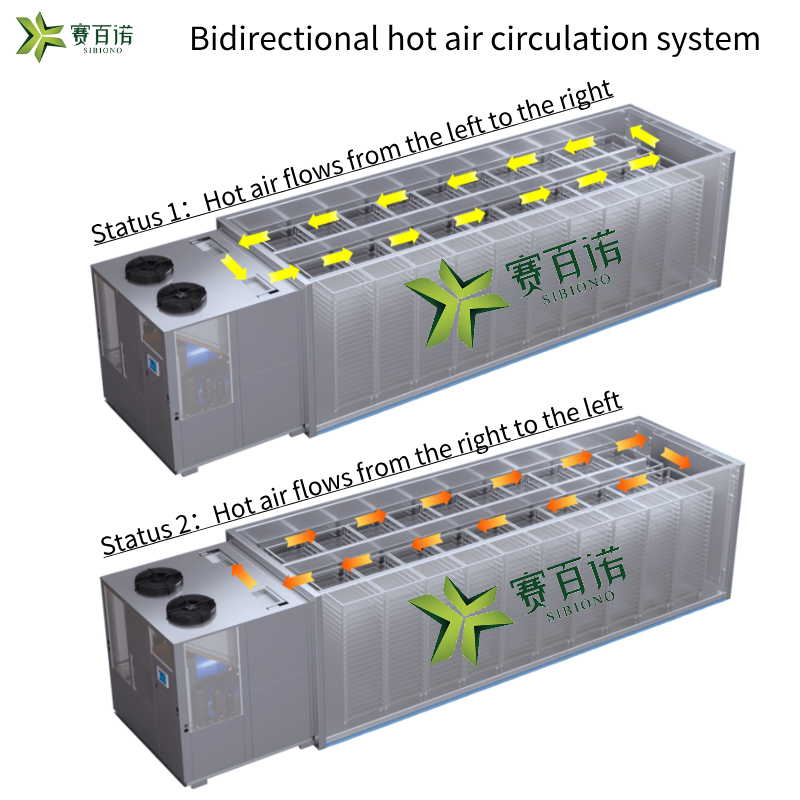

- Equipped with a timed and reversible hot air circulation system, it significantly improves the uniformity of batch drying;

2. Outdated hot air circulation system

- The outdated hot air circulation system operates with airflow in a fixed unidirectional pattern. This leads to uneven temperature distribution within the chambercausing defects such as over-drying in some areas and insufficient drying in others within the same batch.

- The principle of generating temperature diference:In the hot air circulation, when hot air comes into contact with the product the product willabsorb heat from thehot air, causing the temperature of the hot air to continue to decrease.

- For example, as shown in the following figure, 2 old heat pump dryer solutions.

3. Our heat pump dryer hot air circulation system?

- The SlBlONO Heat Pump Drying machine is engineered to deliver exceptional drying uniformity across all batchesIts advanced system combines intelligent airflow design, precise temperature control, and consistent humidity management to eliminate localized over-drying or under-drying.

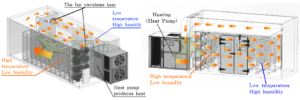

- We can see 3 different capacity specifications of Heat Pump Drying machines in the following figure, all of which have reversible hot air circulation systems.

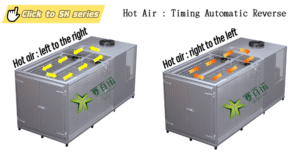

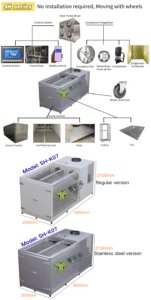

3.1. SH series : Small Heat Pump Dryer

Input capacity 500-700KG/batch

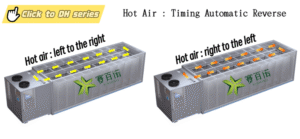

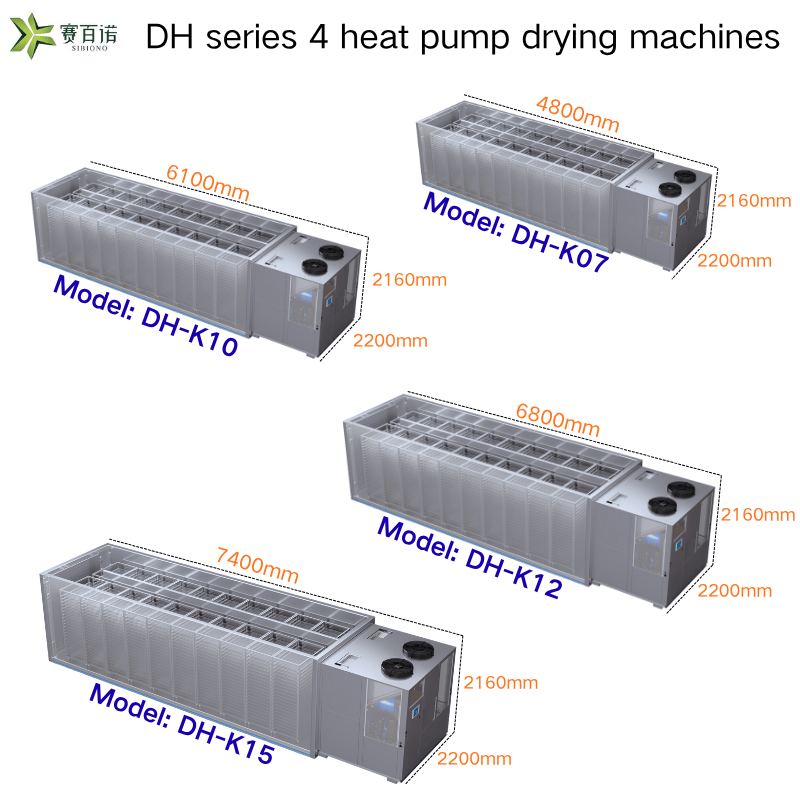

3.2. DH series:Medium Heat Pump Dryer

This series has 4 models, Input capacity 700-1500KG/batch

3.3. MH series:Large Heat Pump Dryer Machine

This series has 4 models, Input capacity 1100-3000KG/batch

4.SH Series Specification

Specification of (SH series) Heat Pump Dryer

- Features : With wheels, movable,reversible wind direction,small to medium-sized capacity (500-700KG/batch)

- Applications: food, fruits, meat (fish/shrimp/beef), vegetables, spices, pet food, industrial products, etc

|

Specification of SH-K07 |

||||

|

Model |

SH-K07 | SH-K07 | SH-K07 | |

|

Material No. |

MH01 | MH02 | MH03 | |

| Power input(including fan) | KW |

12.4 |

||

| power supply | V/PH/HZ |

380V-3PH 50/60HZ |

||

| Max dehumidity | L/H |

40 |

||

| Input capacity | KG/batch |

500-700 |

||

| Dimensions | mm |

L4950*W2000*H2130 |

||

| Qty of trolley | unit |

8 |

||

| Qty of tray | Pieces |

160 |

||

| Heat pump Enclosure material | / | Spray painted | SUS201 | SUS304 |

| Chamber material | / | Coated Steel | SUS304 | SUS304 |

| Tray material | / | SUS304 | SUS304 | SUS304 |

| Trolley material | / | SUS201 | SUS304 | SUS304 |

| Functions |

Heat dry, Cool dry, Dehumidify |

|||

| Blowing type |

Horizontal wind + Bidirectional hot air circulation |

|||

| Installation method |

No need to install, just connect to the power supply upon arrival and it can be used |

|||

5.DH Series Specification

Specification of (DH series) Heat Pump Dryer

- Features: Easy installation, reversible wind direction, medium to large capacity (700-1500KG/batch)

- Applications: food, fruits, meat (fish/shrimp/beef), vegetables, spices, pet food, industrial products, etc

|

4 models of DH series heat pump drying machines |

|||||

|

Model |

DH-K07 | DH-K10 | DH-K12 | DH-K15 | |

| Power input (including fan) |

KW | 12.7 | 17.5 | 19.1 | 20.7 |

| power supply | V/PH/HZ |

380V/3PH,50/60HZ |

|||

| Max dehumidity | L/H | 40 | 55 | 60 | 80 |

| Input capacity | KG/batch | 700 | 1100 | 1300 | 1500 |

| Dimensions | m | 4.8*2.2*2.16 | 6.1*2.2*2.16 | 6.8*2.2*2.16 | 7.4*2.2*2.16 |

| Qty of trolley | unit | 8 | 12 | 14 | 16 |

| Qty of tray | Pieces | 192 | 288 | 336 | 384 |

| Functions |

Heat dry, Cool dry, Dehumidify |

||||

| Blowing type |

Horizontal wind + Bidirectional hot air circulation |

||||

| Installation method |

Installation upon arrival, modular and simple |

||||

6.MH Series Specification

Specification of (MH series) Heat Pump Dryer

- Features: Easy installation, reversible wind direction,double heat pump dryer, large capacity (1100-3000KG/batch)

- Applications: food, fruits, meat (fish/shrimp/beef), vegetables, spices, pet food, industrial products, etc

|

4 models of MH series heat pump drying machines |

|||||

|

Model |

MH-15E | MH-15E-L | MH-30E | MH-30E-L | |

| Power input (including fan) |

KW | 24.8 | 24.8 | 41.4 | 41.4 |

| power supply | V/PH/HZ |

380V/3PH,50/60HZ |

|||

| Max dehumidity | L/H | 80 | 80 | 160 | 160 |

| Input capacity | KG/batch | 1100 | 1500 | 1800-2000 | 2500-3000 |

| Dimensions | m | 7.8*2.2*2.16 | 9*2.2*2.16 | 10.7*2.2*2.16 | 12.5*2.2*2.16 |

| Qty of trolley | unit | 12 | 16 | 20 | 26 |

| Qty of tray | Pieces | 288 | 384 | 480 | 624 |

| Functions |

Heat dry, Cool dry, Dehumidify |

||||

| Blowing type |

Horizontal wind + Bidirectional hot air circulation |

||||

| Installation method |

Installation upon arrival, modular and simple |

||||

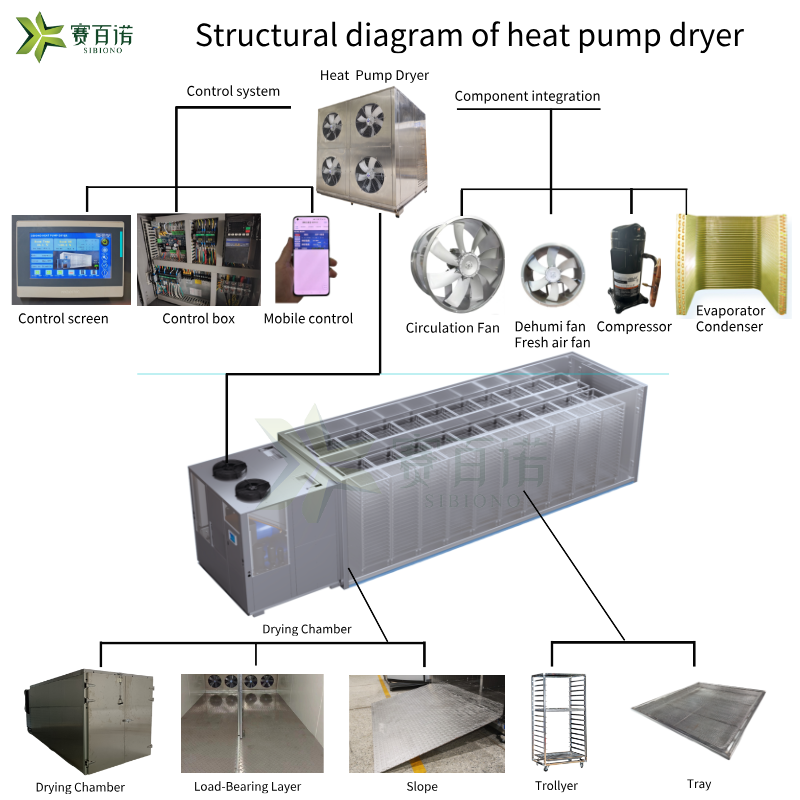

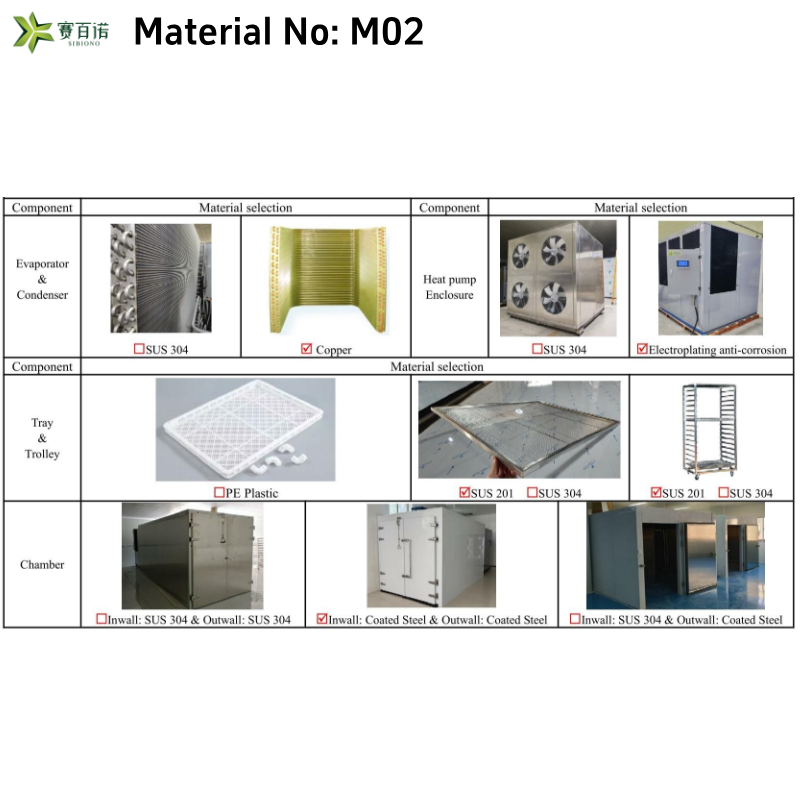

7.Details of drying machine

![]()

![]()

![]()

![]()

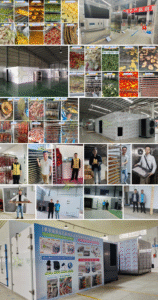

8.Our clients and projects

9.Packing & Delivery

Shipping Instructions

- LCL (Less than Container Load) : All dryers and their accessories are packed in wooden boxes;

- FCL (Full Container Load) : Heat pump is packed in a wooden box, while other accessories are loaded as loose parts.

- Shipping Mark: HEAT PUMP

- HS Code: 8419399090

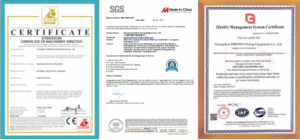

10. Company Profile

Guangzhou SIBIONO Drying Equipment Co., Ltd.,

10.1 About Us

- The company was established in 2016, focusing on the research and development, production, and sales of drying equipment.

- The company goal is to provide the world with smarter, more environmentally friendly, and more uniform drying machines

- SIBIONO has a production base of more than 16,000 square meters.

- SIBIONO has more than 70 professional drying equipment Employees. Provide customized production services for the drying needs of customers all over the world.

10.2 Our service

- ODM service.

- Customize and produce high-quality drying equipment for each customer.

- Provide free technical and training services for heat pump drying equipment.

- Provide 1 year warranty.

- Provide online technical guidance, installation guidance, and maintenance guidance.

11. FAQ

11.1.Company Establishment & Capacity?

Established in 2016, our facility spans 16,000㎡ per , employs 70 staff, and has a production capacity of 1,000 units/month.

11.2.Customization of Heat Pump Dryers?

1) We provide customized solutions for specialized working conditions:

2) Tailored temperature and humidity control based on product characteristics.

3) Custom sizing (larger or smaller units) according to batch capacity.

4)Open-loop heat pumps for hot climates; closed-loop for cold regions.

11.3.Maximum Hot Air Drying Temperature?

1)Standard models: up to 85°C.

2)Custom models: up to 90°C.

11.4.Minimum Cold Air Drying Temperature?

1)Standard cooling temperature: 10°C.

2)Inverter technology and electric auxiliary defrost prevent frost formation.

11.5.Compressor Brand?

Copeland (USA).

11.6.Electronic Expansion Valve (EEV)?

Yes, SANHUA EEV.

11.7.Contactor & Thermal Overload Brand?

Schneider Electric (Germany).

11.8.Durability?

Low/no corrosion environments: 8–10 years.

Highly corrosive conditions: SUS316+SUS304 material recommended.

Increases cost but ensures 8–10 years service life.

11.9. Ventilation Requirements for Sealed Workshops?

1)Fully sealed dehumidification heat pumps: Not required,but unit dehumidification capacity must be doubled to maintain efficiency.

2) Semi-sealed units: Required. Moist air must be expelled externally.

11.10. Pre-Installation Requirements?

1) Adequate flat and prepared space.

2) Sufficient power supply.

3)Professional recommendations provided upon confirmation of capacity and site dimensions.

11.11.Is the installation process of a dryer complicated?

1)For our exported heat pump dryer, in order to reduce the installation cost for customers, we have made many modular designs

that are easy to install;

2)By comparing the two pictures below, you can see that the installation of our dryer is very simple, while the installation of

dryers in other factories is very complex;

3)We strive to reduce installation costs for our customers through modular integrated design.

Reviews

There are no reviews yet.