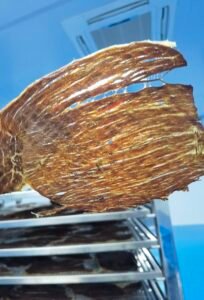

High-Capacity 500KG Beef Crispy Chips Drying Process in 6 Hours

Our industrial-grade beef dryer is engineered for large-scale food processing facilities. This page details the efficient, 6-hour drying cycle that transforms 500KG of raw beef slices into perfectly crispy, shelf-stable chips per batch. Using a precise low-temperature ramp, we ensure optimal texture, flavor, and food safety.

The Precision 6-Hour Drying Cycle for 500KG Batches

This automated process guarantees consistent results for high-volume production of beef crispy chips.

-

Phase 1: Gentle Pre-Drying & Moisture Equalization (45°C – 55°C | First ~1.5 Hours)

The cycle begins at a lower temperature to gently remove surface moisture from the 500KG of beef slices. This crucial step allows for internal moisture to migrate to the surface without case-hardening the exterior. Uniform airflow across all trays ensures every slice starts drying evenly, which is vital for achieving a consistent crispness. -

Phase 2: Active Dehydration & Flavor Lock-In (Gradually Ramp to 65°C – 72°C | Hours 2-4.5)

The temperature is systematically increased to accelerate moisture removal. During this core phase, over 80% of the moisture is efficiently extracted. The controlled, low-temperature approach helps preserve the beef’s natural proteins and flavor compounds, preventing them from being denatured by excessive heat, resulting in a superior taste and texture. -

Phase 3: Pasteurization & Final Crisping (74°C – 78°C | Final ~1 Hour)

To ensure product safety and stability, the temperature is elevated to the pasteurization range. This critical step eliminates potential pathogens, giving the beef crispy chips a long shelf life. The final heat application also sets the perfect, brittle texture that consumers desire, completing the process in just 6 hours.

Key Advantages of Our 500KG Beef Crispy Chips Dryer:

-

Massive Batch Capacity: Handle 500KG of product per cycle, ideal for large-scale operations.

-

Time Efficiency: A complete drying cycle in only 6 hours boosts your production throughput.

-

Superior Product Quality: Precision temperature control guarantees uniform crispness, color, and flavor retention across the entire batch.

-

Guaranteed Food Safety: The integrated pasteurization phase ensures your product meets all microbial safety standards.

-

Energy Optimized: Advanced insulation and heat recovery systems make this large-capacity dryer highly energy-efficient.

Ready to Scale Your Beef Crisps Production?

If you require a reliable, high-capacity drying solution for your commercial beef crispy chips operation, our 500KG/batch dryer is the answer. Contact us today for a detailed quotation and technical specifications tailored to your needs.