Corn Drying and Processing: 5000KG Industrial Workflow with Heat Pump Technology

Introduction

Commercial corn drying is essential for grain preservation, preventing mold growth, and maintaining market quality. For large-scale operations processing 5000KG batches, selecting appropriate drying technology significantly impacts final product quality, operational costs, and profitability. This technical overview examines industrial corn processing using advanced Heat Pump Dryers compared to conventional Electric Heating Dryers.

Industrial Corn Drying Protocol

1. Pre-drying Preparation

-

Receiving & Cleaning: Incoming corn undergoes preliminary cleaning to remove husks, stalks, and foreign materials

-

Moisture Testing: Initial moisture content measurement (typically 25-35% for freshly harvested corn)

-

Quality Sorting: Removal of damaged kernels to ensure uniform drying

2. Drying Process Parameters

-

Loading: Uniform distribution in drying chamber using automated conveyor systems

-

Temperature Control: Maintained at 40-55°C (104-131°F) for optimal quality preservation

-

Moisture Reduction: Target final moisture content: 12-15% for safe storage

-

Processing Time: 6-10 hours depending on initial moisture levels

3. Post-drying Handling

-

Cooling Cycle: Gradual temperature reduction to ambient levels

-

Quality Inspection: Moisture verification and quality assessment

-

Storage Preparation: Packaging in breathable containers for grain storage

Technology Comparison: Heat Pump vs Electric Dryers

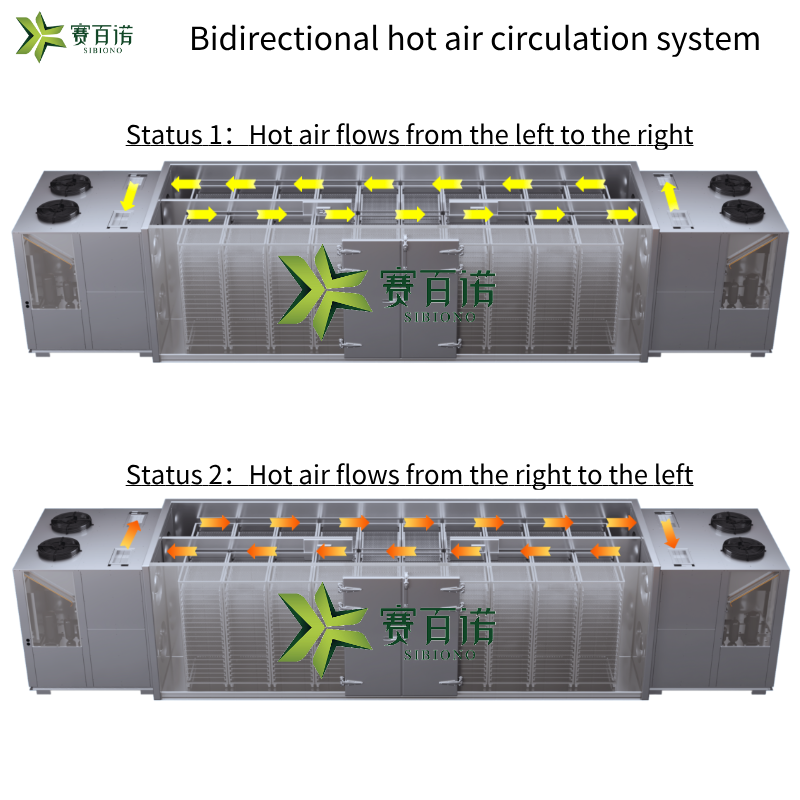

Heat Pump Dryer Advantages

-

Energy Efficiency

-

60-70% reduced energy consumption compared to electric dryers

-

Heat recovery system minimizes thermal loss

-

Lower operational costs per kilogram

-

-

Quality Preservation

-

Precise temperature control (±2°C) prevents kernel damage

-

Even humidity distribution maintains nutritional integrity

-

Gentle drying prevents stress cracking in kernels

-

-

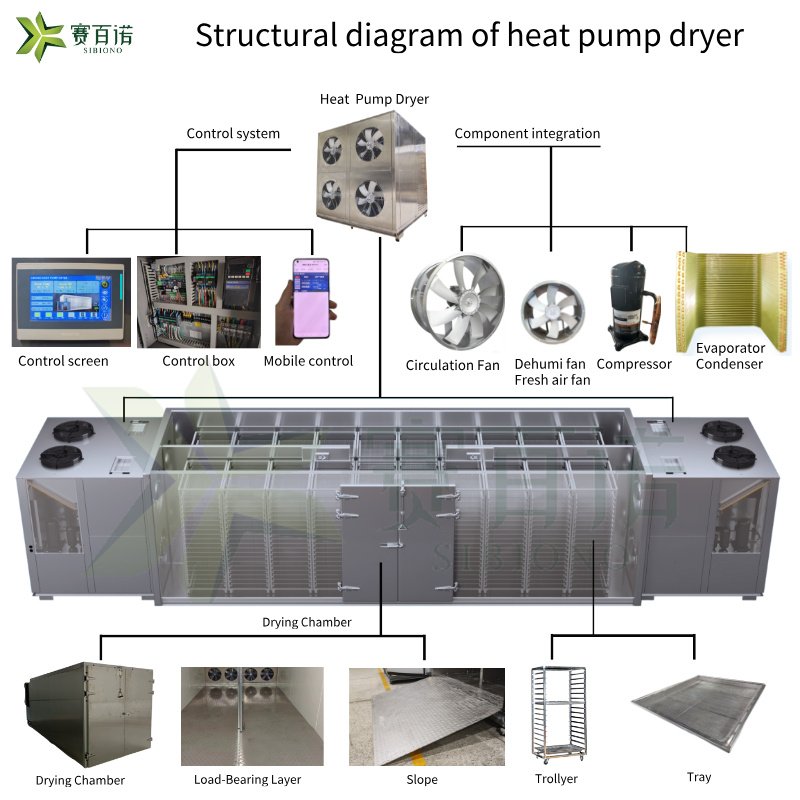

Operational Benefits

-

Consistent batch quality through automated control systems

-

Lower maintenance requirements

-

Reduced fire risk through indirect heating

-

Electric Heating Dryer Limitations

-

High Operational Costs

-

Direct resistance heating consumes 2-3× more energy

-

Significant heat loss through ventilation

-

Higher peak power demand charges

-

-

Quality Concerns

-

Hot spots causing uneven drying

-

Risk of over-drying and nutrient degradation

-

Higher percentage of stress-cracked kernels

-

-

Maintenance Issues

-

Frequent heating element replacement

-

Higher electrical component failure rates

-

Increased fire safety requirements

-

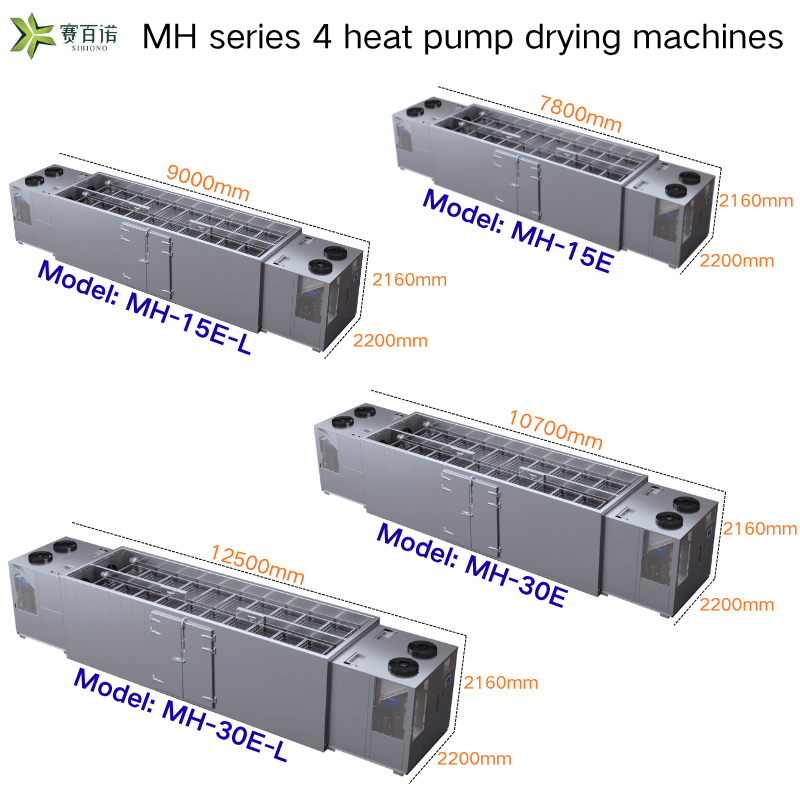

Technical Specifications for 5000KG Capacity

-

Drying Chamber Volume: 15-20m³

-

Power Configuration: 380V/3Phase/50Hz

-

Dehumidification Capacity: 150-200L/hour

-

Thermal Efficiency: ≥400%

-

Control System: PLC with touchscreen interface

Conclusion

The 5000KG Heat Pump Dryer represents the optimal solution for commercial corn processing, combining significant energy savings with superior product quality. While electric dryers offer lower initial investment, their higher operational costs and inconsistent results make heat pump technology the economically superior choice for large-scale operations. The precision control and energy recovery systems in modern heat pump dryers ensure maximum profitability while maintaining the highest grain quality standards for both domestic and international markets.