Industrial Drying Process for 1500KG Pet Food: Advanced Heat Pump Technology for Premium Pet Nutrition

Introduction

Modern pet food production requires sophisticated drying technologies that preserve nutritional quality while ensuring product safety and palatability. For large-scale operations processing 1500KG batches of various pet food formulations, selecting optimal drying technology is crucial for manufacturing high-value pet treats that meet stringent quality standards. This comprehensive analysis examines industrial pet food drying using advanced Heat Pump Dryers compared to conventional Electric Heating Dryers.

Pet Food Drying and Processing Protocol

1. Raw Material Preparation

-

Material Selection: Human-grade meats, fish, vegetables, and grains

-

Formulation & Mixing: Precise ingredient blending according to nutritional requirements

-

Shape Formation: Extrusion or molding into consistent shapes and sizes

-

Quality Verification: Raw material testing for contaminants and nutritional content

2. Pre-drying Treatment

-

Loading Optimization: Strategic tray arrangement for maximum airflow

-

Surface Preparation: Uniform coating application if required

-

Sanitation Protocol: Comprehensive UV and steam sterilization

-

Weight Recording: Initial batch weight documentation

3. Multi-Stage Drying Parameters

-

Phase 1 (Pre-drying – 2-3 hours):

-

Temperature: 45-50°C

-

Humidity: 55-60% RH

-

Purpose: Initial moisture reduction and structure setting

-

-

Phase 2 (Primary Drying – 8-12 hours):

-

Temperature: 55-65°C

-

Humidity: 45-50% RH

-

Purpose: Core moisture removal and flavor development

-

-

Phase 3 (Final Drying – 3-4 hours):

-

Temperature: 65-70°C

-

Humidity: 35-40% RH

-

Purpose: Pathogen control and texture finalization

-

-

Phase 4 (Conditioning – 1-2 hours):

-

Temperature: 40-45°C

-

Humidity: 30-35% RH

-

Purpose: Moisture equalization and cooling

-

4. Quality Control & Packaging

-

Moisture Analysis: Target 10-12% final moisture content

-

Nutritional Testing: Protein, fat, and nutrient verification

-

Texture Assessment: Consistent chewiness and hardness

-

Microbial Safety: Comprehensive pathogen screening

-

Packaging: Modified atmosphere packaging for freshness

Technology Comparison: Heat Pump vs Electric Dryers

Heat Pump Dryer Advantages for Pet Food Production

1. Superior Product Quality

-

Nutrient Preservation: Maintains essential vitamins, amino acids, and proteins

-

Palatability Enhancement: Develops natural flavors pets prefer

-

Texture Consistency: Uniform drying prevents hard spots and maintains chewiness

-

Color Retention: Preserves natural appearance for consumer appeal

2. Technical Superiority

-

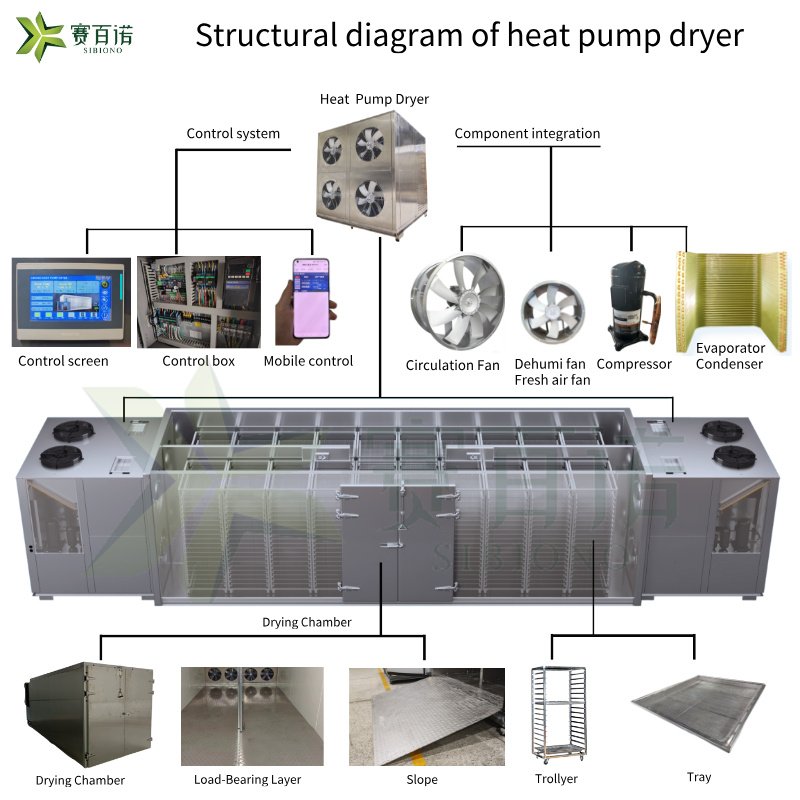

Precision Control: ±0.8°C temperature and ±2.5% RH humidity accuracy

-

Energy Efficiency: 60-70% reduction in energy consumption

-

Automated Operation: Programmable recipes for different formulations

-

Hygienic Design: Easy-clean surfaces and bacterial growth prevention

3. Economic Benefits

-

Operating Cost Reduction: Significant energy savings per production cycle

-

Quality Premium: Superior products command higher market prices

-

Reduced Waste: Consistent results minimize production losses

-

Regulatory Compliance: Meets international pet food safety standards

Electric Heating Dryer Limitations

1. Quality Challenges

-

Nutrient degradation from excessive heat exposure

-

Uneven drying causing texture inconsistencies

-

Color changes and surface scorching

-

Flavor loss affecting product palatability

2. Operational Disadvantages

-

High energy consumption (3.5-4.5 kWh per kg)

-

Limited humidity control capabilities

-

Temperature fluctuations affecting batch consistency

-

Higher maintenance frequency and costs

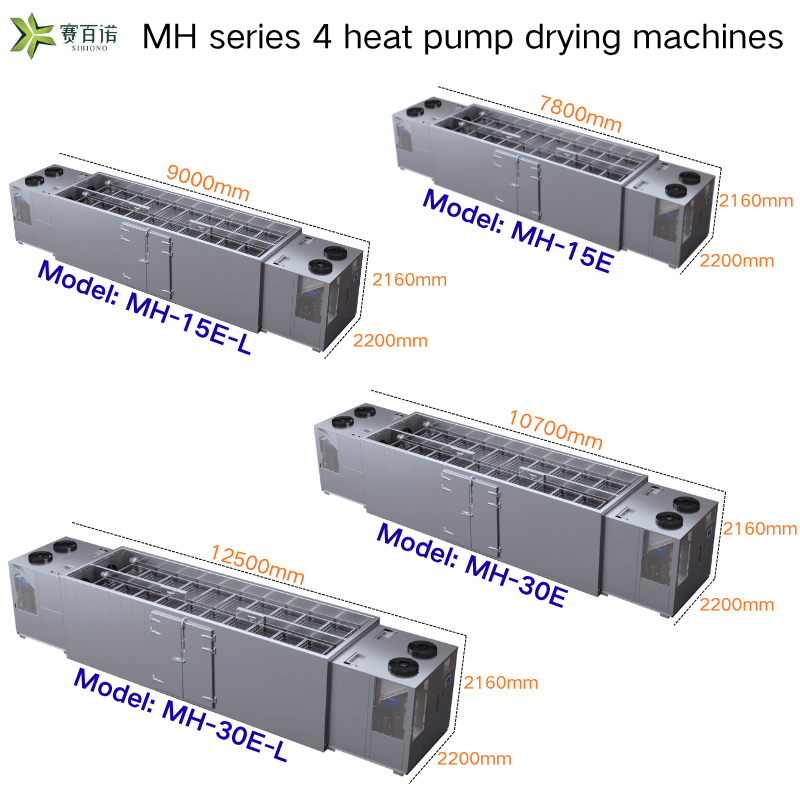

Technical Specifications – 1500KG Capacity

-

Drying Chamber Volume: 35-45m³

-

Temperature Range: 40-75°C (±0.8°C accuracy)

-

Humidity Control: 25-65% RH (±2.5% precision)

-

Drying Time: 14-21 hours depending on formulation

-

Power Requirements: 380V/3Phase/65-85A

-

Control System: Industrial PLC with recipe management

Conclusion

The 1500KG Heat Pump Dryer represents the pinnacle of commercial pet food drying technology, delivering unmatched product quality, operational efficiency, and production consistency. While electric dryers may appear economically attractive initially, the heat pump technology’s superior environmental control and energy efficiency make it indispensable for manufacturers producing premium pet foods. The technology’s ability to preserve nutritional integrity while significantly reducing operational costs ensures outstanding return on investment for pet food companies committed to producing healthy, high-quality products that meet evolving market demands and consumer expectations for premium pet nutrition.