Drying and Processing of 1500KG Mangoes: Achieving Premium Quality with Advanced Drying Technology

Introduction

Mangoes, known as the “king of fruits,” require careful handling to preserve their exquisite flavor, vibrant color, and nutritional value during drying. For industrial operations processing 1500KG batches, the choice of drying technology is paramount to producing a premium product that commands top value in the market. This guide details the commercial mango drying process and provides a critical comparison between the advanced Heat Pump Dryer and the conventional Electric Heating Dryer.

Industrial Mango Drying and Processing Workflow

-

Selection and Sorting: The process begins with selecting fully ripe, firm mangoes with high sugar content and minimal fiber. They are sorted to remove damaged or diseased fruits.

-

Washing and Peeling: Mangoes are thoroughly washed. Depending on the final product (slices, chunks), they are then peeled, often mechanically, to remove the skin.

-

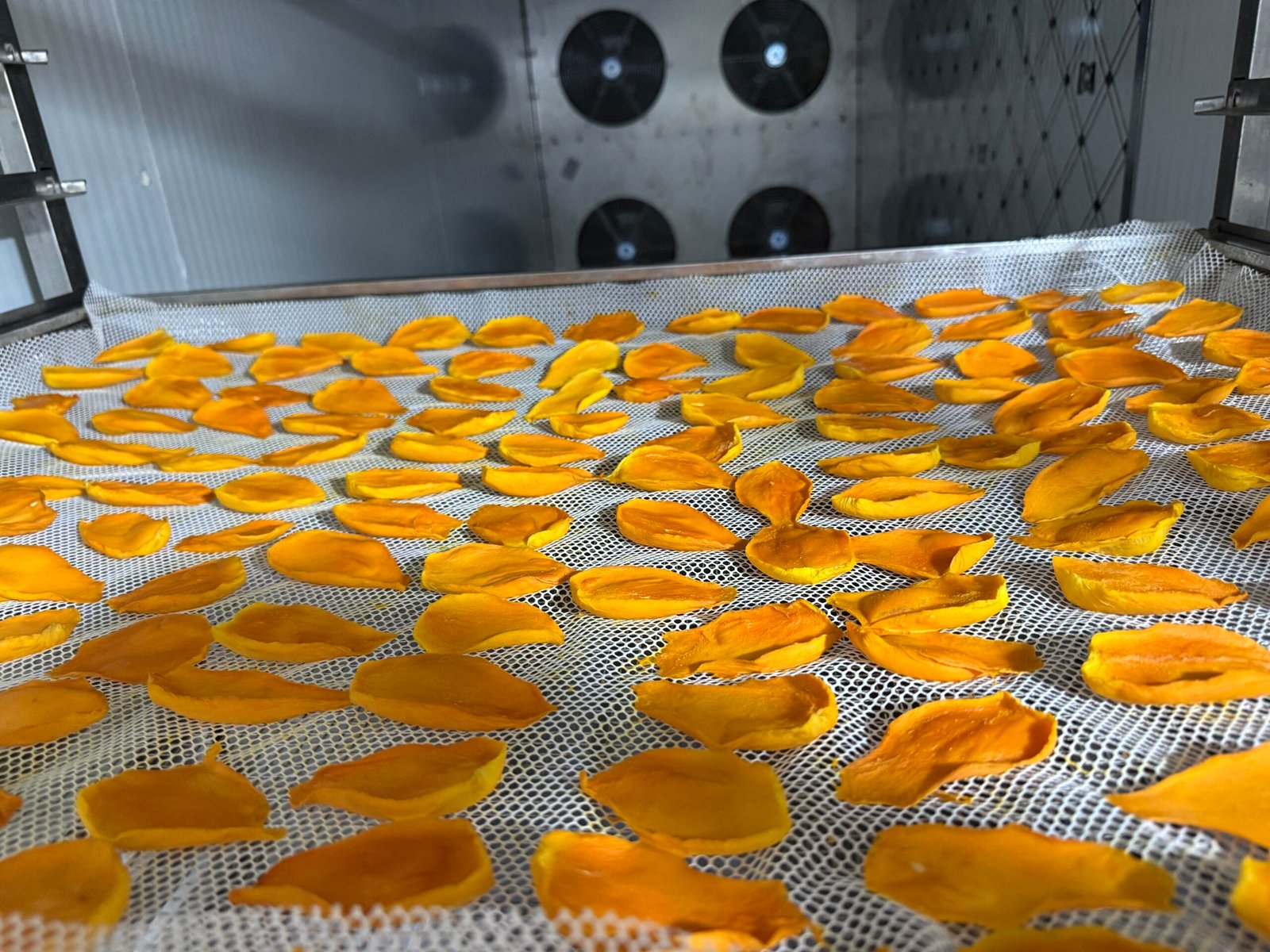

Slicing/Pitting: The fruit is de-stoned (pitted) and sliced into uniform pieces—slices, chunks, or dices—to ensure consistent drying rates across the entire batch.

-

Pretreatment (Optional): To preserve the bright yellow-orange color (carotenoids) and prevent browning, mango pieces are often treated. This can involve:

-

Blanching: Brief exposure to steam or hot water.

-

Dipping: Immersion in a solution of ascorbic acid (vitamin C) or citric acid.

-

-

Loading and Drying: The prepared mango pieces are spread evenly on trays and loaded into the 1500KG capacity dryer. Drying is conducted at low temperatures, typically between 50°C and 65°C (122°F – 149°F). Precise humidity control is crucial to remove moisture effectively without case-hardening.

-

Conditioning and Packaging: After drying to a leathery or crisp texture (depending on the target), the mango pieces are cooled. They are often conditioned to equalize moisture before being packaged in vacuum-sealed or nitrogen-flushed bags to maintain freshness, color, and shelf life.

Technology Comparison: Heat Pump Dryer vs. Electric Heating Dryer

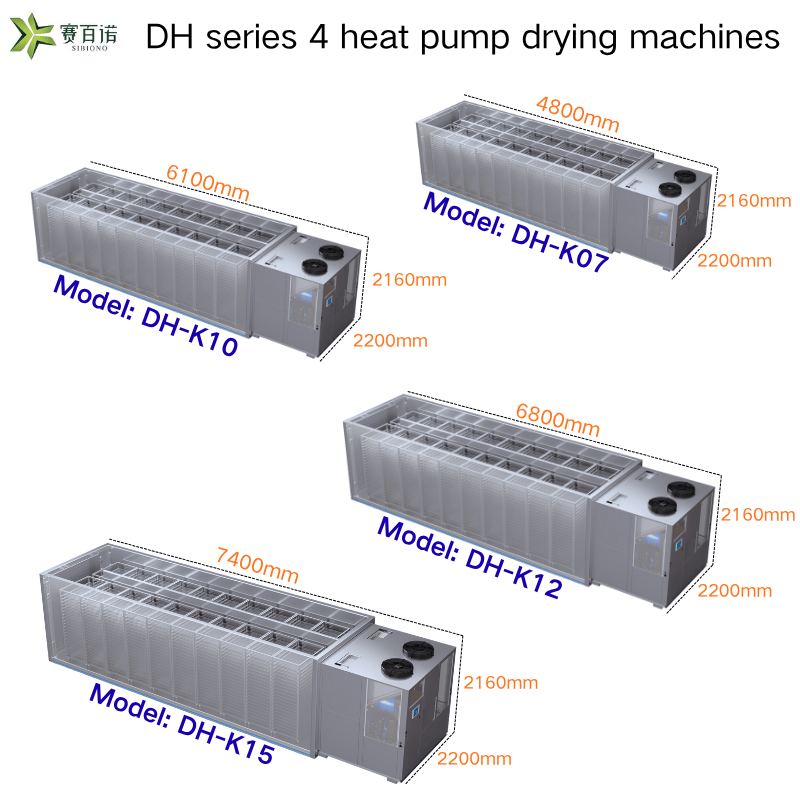

For a 1500KG operation, the drying technology directly influences operational costs and the marketability of the final product.

Heat Pump Dryer: The Standard for Premium Quality

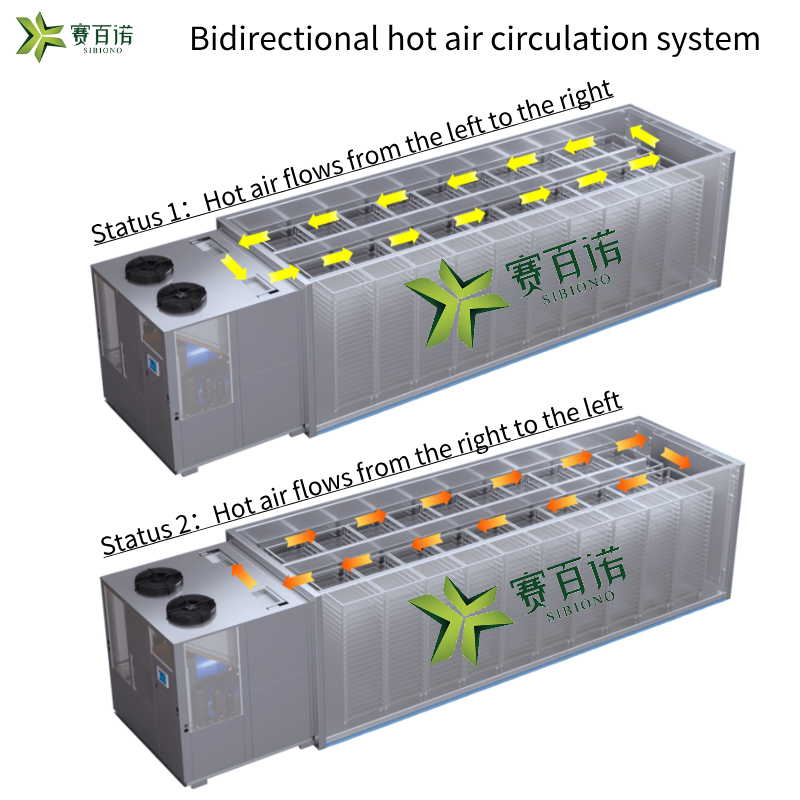

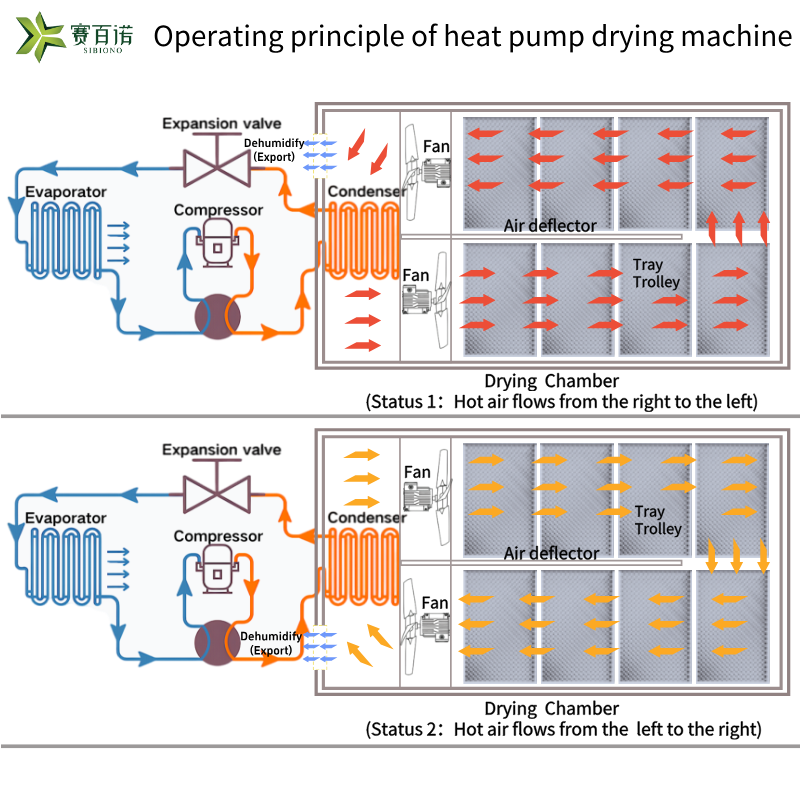

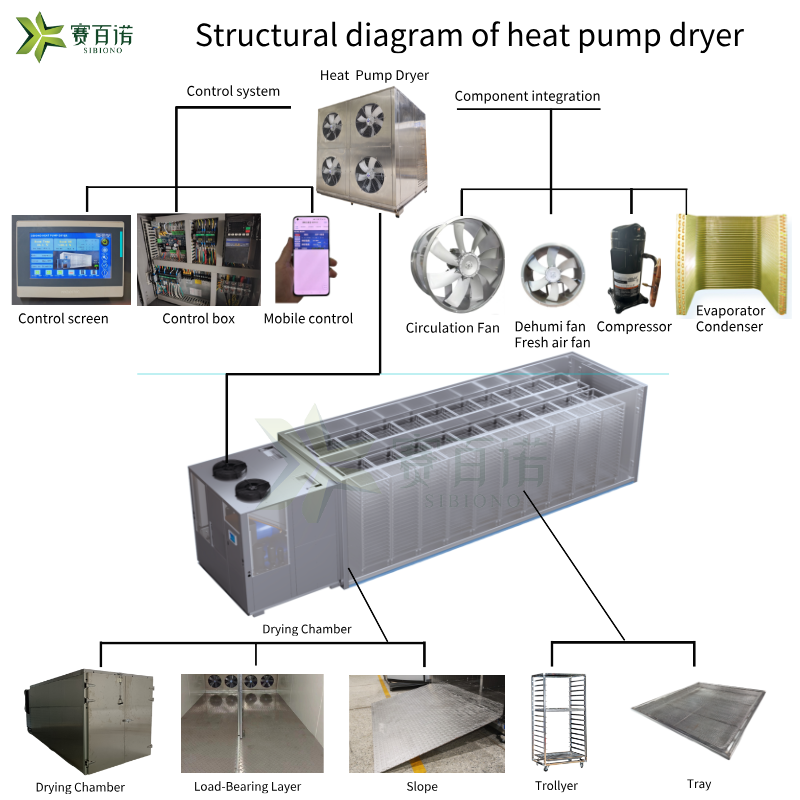

Heat pump dryers use a refrigeration cycle to extract thermal energy from the ambient air, concentrating it in the drying chamber while simultaneously removing moisture.

-

Superior Energy Efficiency: By recycling heat, these dryers achieve energy savings of 60-70% compared to conventional electric dryers. This drastic reduction in electricity consumption makes them the most cost-effective solution for high-volume processing.

-

Unmatched Product Quality: The precise control over temperature and, critically, humidity is essential for mangoes. This gentle drying environment prevents sugar migration and case-hardening, perfectly preserving the fruit’s natural vibrant color, sweet, tropical flavor, and chewy texture. It results in a premium product free from burnt notes or uneven drying.

-

Gentle and Uniform Drying: The closed-loop system ensures a consistent, low-temperature airflow that dries all 1500KG evenly, guaranteeing batch-to-batch consistency.

-

Environmental Sustainability: Significantly lower energy consumption translates to a reduced carbon footprint, aligning with eco-friendly manufacturing practices.

Electric Heating Dryer: The Costly and Risky Alternative

Electric dryers generate heat directly through high-resistance elements, essentially baking the fruit with dry heat.

-

High Operational Costs: The direct conversion of electricity to heat is highly inefficient for dehydration, leading to prohibitively high energy bills for a 1500KG capacity, severely impacting profitability.

-

Significant Quality Deficiencies: The lack of precise humidity control often leads to case-hardening, where the outside of the mango piece becomes hard and leathery while the inside remains moist and prone to spoilage. The intense, dry heat can also caramelize the high sugar content, causing scorching, a dark brown color, and a bitter taste that masks the natural mango flavor.

-

Lower Initial Investment, Higher Long-Term Cost: The primary advantage is a simpler system and a lower purchase price. However, this is quickly negated by exorbitant ongoing energy costs and the production of a lower-quality product that sells for less.

Conclusion: The Strategic Advantage of a 1500KG Heat Pump Dryer for Mangoes

For any commercial processor targeting the lucrative dried fruit market, investing in a 1500KG Heat Pump Dryer is a strategic decision for quality and profitability. It is the only technology that can consistently produce a premium dried mango with the color, flavor, and texture that consumers demand. When combined with massive energy savings, the heat pump dryer not only protects your profit margins but also enhances your brand’s reputation for quality, ensuring a strong return on investment.