Industrial Drying Process for 1000KG Pineapple: Preserving Tropical Quality with Heat Pump Technology

Introduction

Pineapple drying requires careful temperature management to preserve its vibrant color, natural sweetness, and delicate enzymatic structure. For commercial operations processing 1000KG batches, maintaining optimal drying conditions is essential for producing premium dried pineapple that meets international quality standards. This technical analysis examines the industrial pineapple drying process using advanced Heat Pump Dryers compared to conventional Electric Heating Dryers.

Pineapple Drying and Processing Protocol

1. Raw Material Preparation

-

Selection & Grading: Choose ripe pineapples with 12-14°Brix sugar content

-

Peeling & Coring: Automated peeling and removal of core and eyes

-

Slicing & Cutting: Uniform slicing (8-12mm thickness) or dicing (15-20mm cubes)

-

Pretreatment: Optional sulfur dioxide treatment for color preservation

2. Pre-drying Arrangement

-

Tray Loading: Single-layer placement with 30-40% surface coverage

-

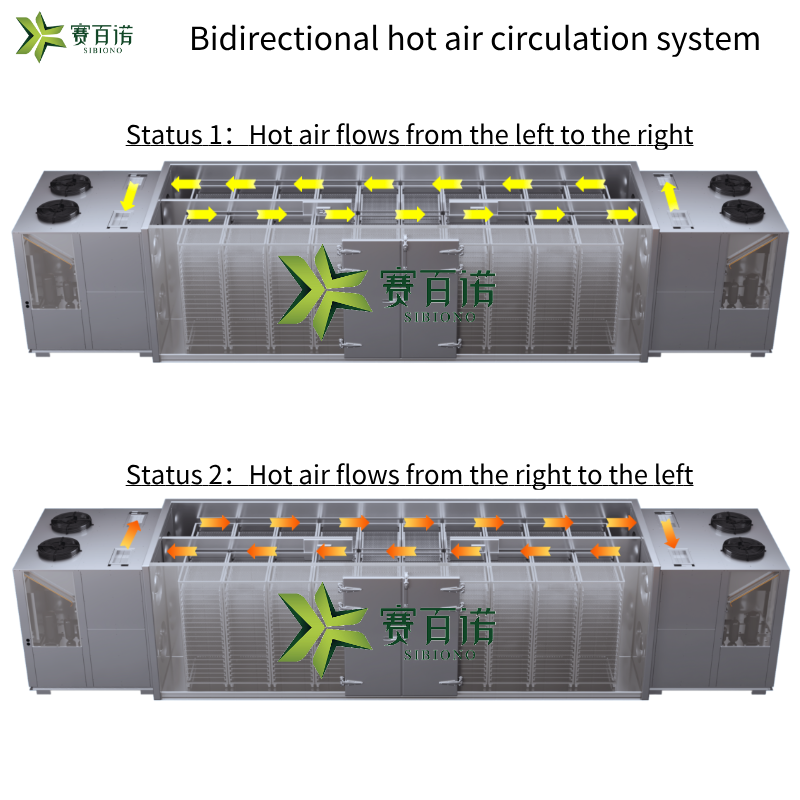

Airflow Optimization: Strategic rack positioning for maximum circulation

-

Sanitization: UV treatment of drying chamber

3. Multi-Stage Drying Parameters

-

Phase 1 (Initial – 2-3 hours):

-

Temperature: 55-60°C

-

Humidity: 45-50% RH

-

Purpose: Surface moisture removal

-

-

Phase 2 (Main – 8-12 hours):

-

Temperature: 58-63°C

-

Humidity: 40-45% RH

-

Purpose: Internal moisture migration

-

-

Phase 3 (Final – 2-3 hours):

-

Temperature: 60-65°C

-

Humidity: 35-40% RH

-

Purpose: Final moisture adjustment

-

4. Post-drying Procedures

-

Conditioning: 1-2 hours moisture equalization

-

Quality Inspection: Moisture content (15-18%), color, and texture evaluation

-

Packaging: Nitrogen flushing or vacuum sealing

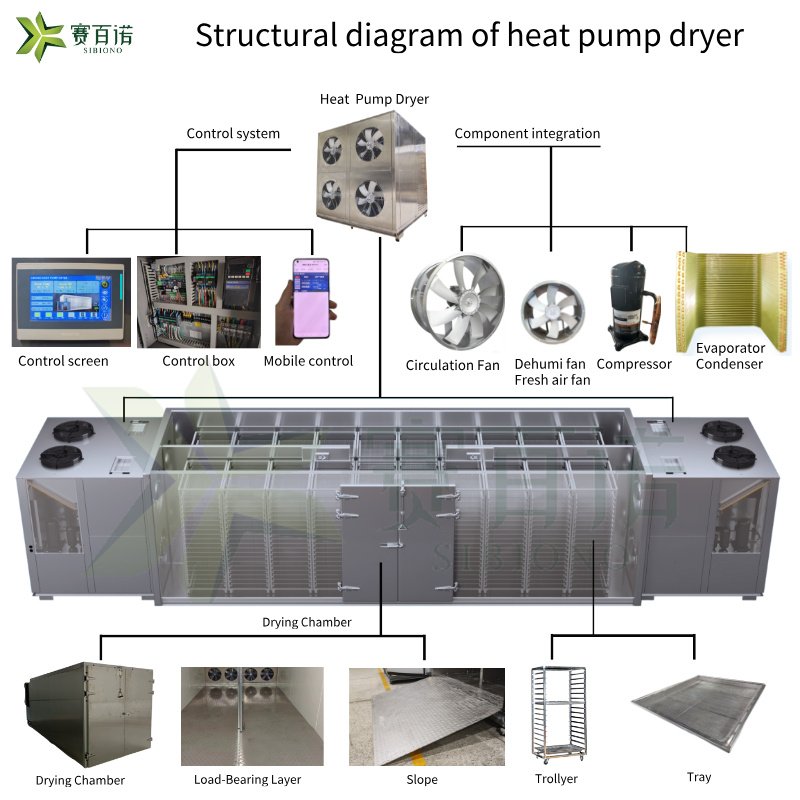

Technology Comparison: Heat Pump vs Electric Dryers

Heat Pump Dryer Advantages for Pineapple Processing

1. Superior Quality Preservation

-

Color Retention: Maintains natural golden-yellow color without darkening

-

Texture Control: Prevents case hardening and maintains chewy texture

-

Flavor Preservation: Protects volatile aroma compounds and natural sweetness

-

Nutrient Conservation: Preserves vitamin C and bromelain enzyme activity

2. Technical Excellence

-

Precise Temperature Control: ±1°C accuracy throughout drying cycle

-

Automatic Humidity Management: ±3% RH precision prevents over-drying

-

Energy Efficiency: 55-65% reduction in energy consumption

-

Gentle Drying: Even air distribution prevents sugar crystallization

3. Economic Benefits

-

Reduced Operating Costs: Lower energy consumption per kilogram

-

Higher Product Value: Premium quality commands better market prices

-

Increased Yield: Controlled drying reduces product loss

-

Lower Maintenance: No heating element replacements needed

Electric Heating Dryer Limitations

1. Quality Problems

-

Sugar caramelization causing darkening

-

Hard exterior with sticky interior

-

Loss of natural pineapple flavor

-

Nutrient degradation from high temperatures

2. Operational Disadvantages

-

High energy consumption (2.8-3.6 kWh per kg)

-

Difficulty maintaining consistent temperatures

-

Poor humidity control leading to quality variations

-

Frequent maintenance requirements

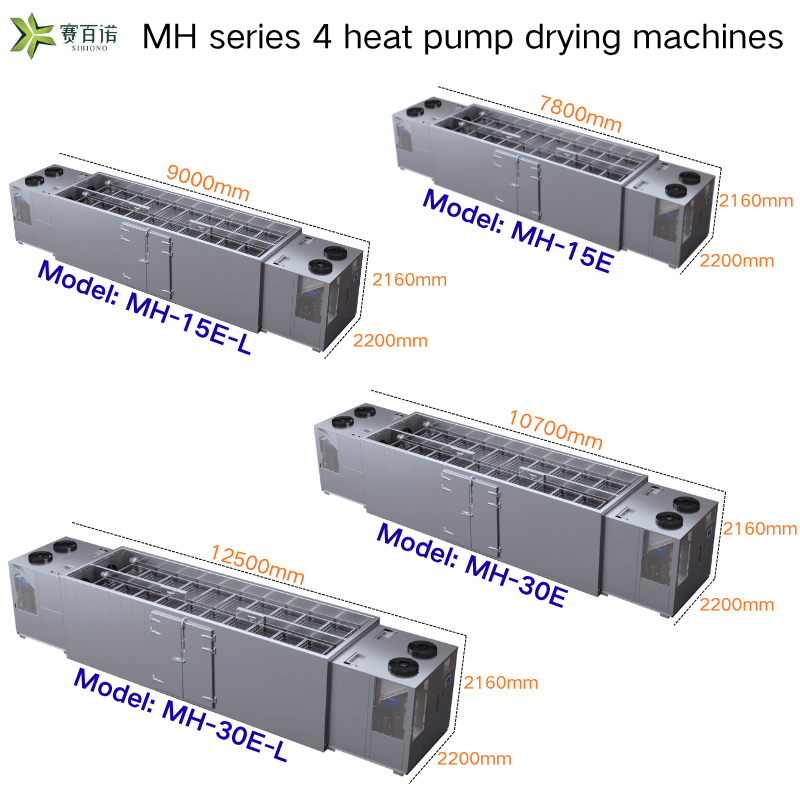

Technical Specifications – 1000KG Capacity

-

Drying Chamber Volume: 18-25m³

-

Temperature Range: 40-70°C (±1°C accuracy)

-

Humidity Control: 30-60% RH (±3% precision)

-

Drying Time: 12-18 hours depending on slice thickness

-

Power Requirements: 380V/3Phase/40-55A

-

Control System: PLC with recipe storage and humidity tracking

Conclusion

The 1000KG Heat Pump Dryer provides the optimal solution for commercial pineapple processing, delivering exceptional product quality, operational efficiency, and cost-effectiveness. While electric dryers may offer lower initial investment, the heat pump technology’s precise environmental control and energy efficiency make it indispensable for producing premium dried pineapple that meets the highest quality standards. The technology’s ability to preserve pineapple’s natural characteristics while significantly reducing operational costs ensures superior return on investment for fruit processors targeting discerning consumers in competitive domestic and international markets.