Industrial Drying Process for 1000KG Pet Food Chicken Breast: Ensuring Quality with Heat Pump Technology

Introduction

The production of premium pet food requires careful drying processes that preserve nutritional integrity while ensuring food safety. For commercial operations processing 1000KG batches of chicken breast, selecting the appropriate drying technology is crucial for creating high-value pet treats that meet quality standards and consumer expectations. This analysis examines the industrial pet food drying process using advanced Heat Pump Dryers compared to conventional Electric Heating Dryers.

Pet Food Chicken Breast Drying Protocol

1. Raw Material Preparation

-

Selection & Inspection: Fresh, human-grade chicken breast with proper certification

-

Trimming & Preparation: Removal of excess fat and connective tissue

-

Slicing & Sizing: Uniform slicing (8-15mm thickness) based on product specifications

-

Marination (Optional): Application of pet-safe flavor enhancers or nutrients

2. Pre-drying Treatment

-

Arrangement: Single-layer placement on hygienic drying trays

-

Surface Treatment: Pat drying to remove excess moisture

-

Sanitization: UV treatment of drying chamber and equipment

3. Multi-Stage Drying Parameters

-

Phase 1 (Initial – 1-4 hours):

-

Temperature: 65-70°C

-

Humidity: 50-55% RH

-

Purpose: Surface moisture removal and protein setting

-

-

Phase 2 (Main – 4-8 hours):

-

Temperature: 55-60°C

-

Humidity: 20-45% RH

-

Purpose: Internal moisture migration and pathogen control

-

-

Phase 3 (Final – 8-10 hours):

-

Temperature: 50-55°C

-

Humidity: 10-15% RH

-

Purpose: Final moisture adjustment and texture formation

-

4. Quality Assurance & Packaging

-

Moisture Testing: Target 12-15% final moisture content

-

Texture Analysis: Consistent chewiness and flexibility

-

Microbial Testing: Salmonella and E. coli screening

-

Packaging: Nitrogen flushing for freshness preservation

Technology Comparison: Heat Pump vs Electric Dryers

Heat Pump Dryer Advantages for Pet Food Production

1. Nutritional Quality Preservation

-

Protein Integrity: Gentle drying preserves protein quality and digestibility

-

Nutrient Retention: Maintains essential amino acids and vitamins

-

Natural Color: Preserves appealing natural appearance

-

Flavor Enhancement: Develops natural meat flavor pets prefer

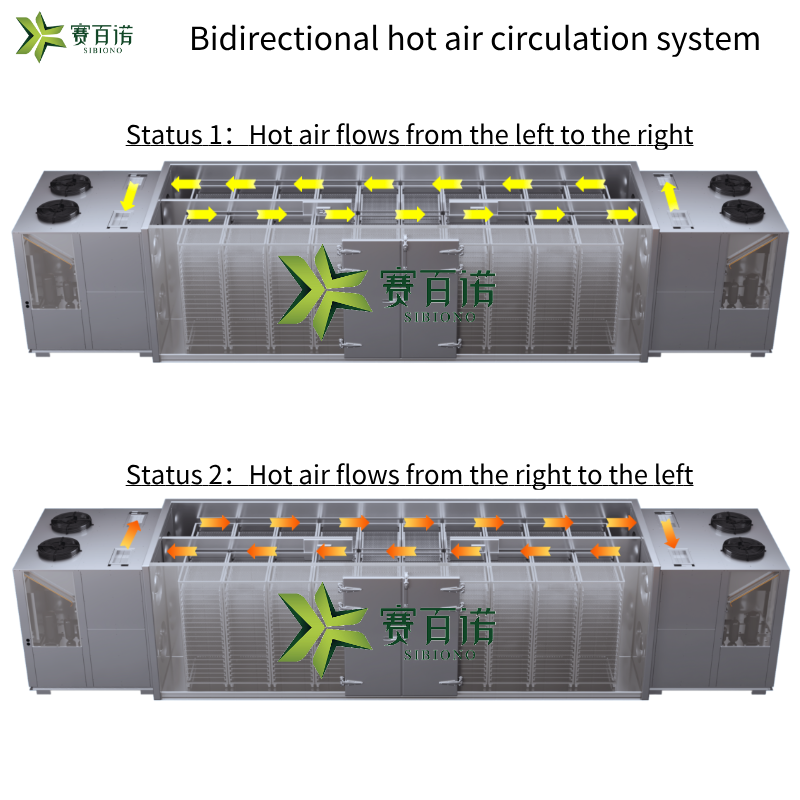

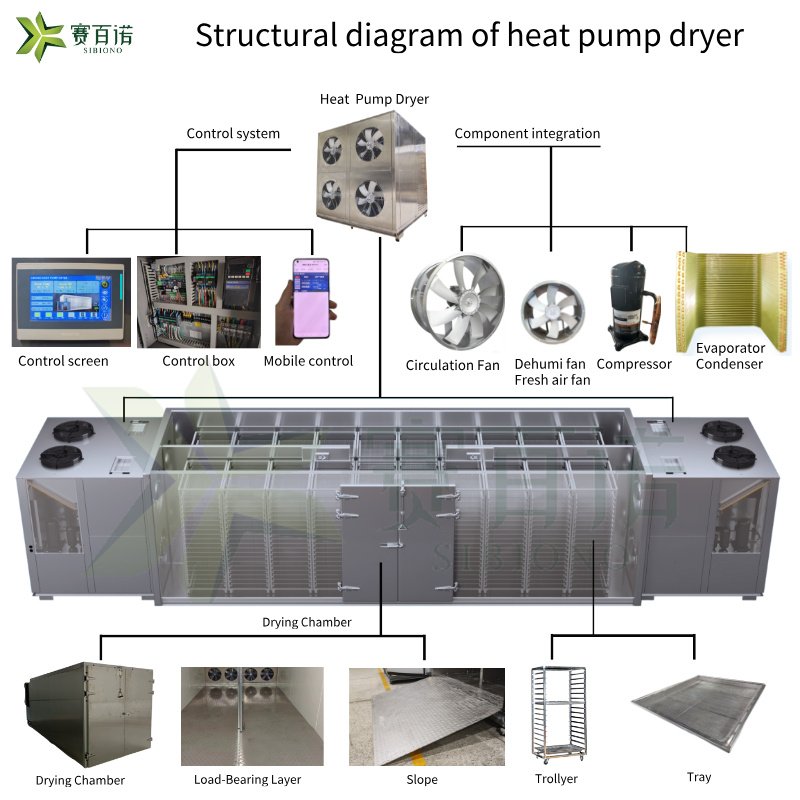

2. Technical Excellence

-

Precise Temperature Control: ±1°C accuracy for consistent results

-

Automatic Humidity Management: ±3% RH precision prevents over-drying

-

Energy Efficiency: 55-65% reduction in energy consumption

-

Hygienic Operation: Closed-loop system prevents contamination

3. Economic Benefits

-

Reduced Operating Costs: Lower energy consumption per kilogram

-

Higher Product Value: Premium quality commands better market prices

-

Increased Shelf Life: Proper drying extends product longevity

-

Regulatory Compliance: Meets pet food safety standards

Electric Heating Dryer Limitations

1. Quality Concerns

-

Protein denaturation affecting nutritional value

-

Uneven drying causing texture inconsistencies

-

Color degradation and surface burning

-

Loss of natural flavors and aromas

2. Operational Challenges

-

High energy consumption (3.2-4.2 kWh per kg)

-

Difficulty maintaining consistent temperatures

-

Poor humidity control leading to quality variations

-

Higher maintenance and replacement costs

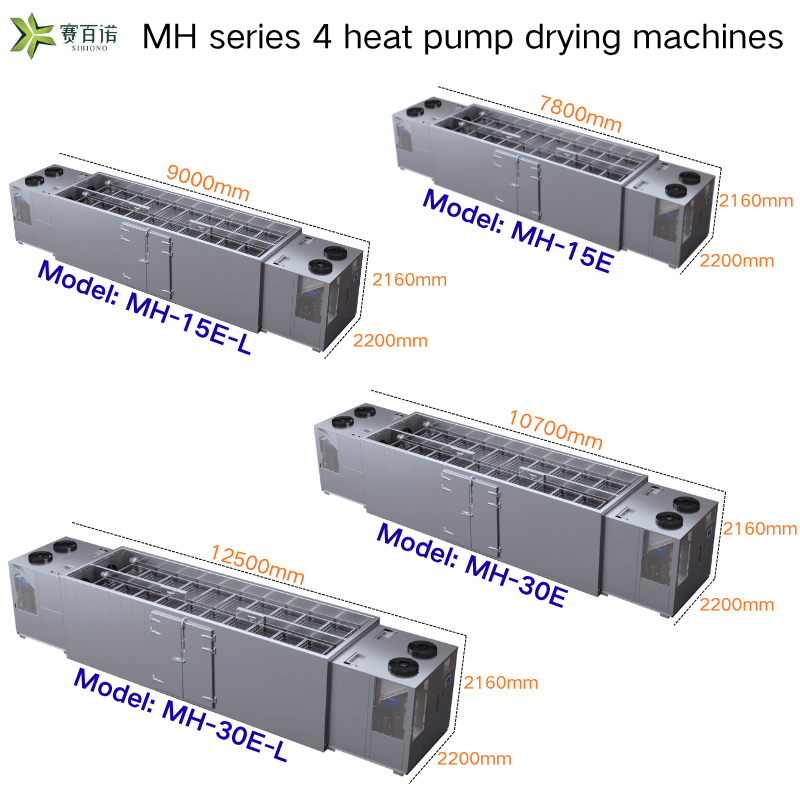

Technical Specifications – 1000KG Capacity

-

Drying Chamber Volume: 22-30m³

-

Temperature Range: 45-75°C (±1°C accuracy)

-

Humidity Control: 30-60% RH (±3% precision)

-

Drying Time: 15-21 hours depending on thickness

-

Power Requirements: 380V/3Phase/50-65A

-

Safety Features: HACCP compliance, automatic shutdown

Conclusion

The 1000KG Heat Pump Dryer provides the optimal solution for commercial pet food chicken breast processing, delivering superior product quality, operational efficiency, and cost-effectiveness. While electric dryers may offer lower initial investment, the heat pump technology’s precise environmental control and energy efficiency make it essential for producing premium pet treats that meet the highest quality and safety standards. The technology’s ability to preserve nutritional value while significantly reducing operational costs ensures excellent return on investment for pet food manufacturers committed to producing healthy, high-quality products for discerning pet owners.