Industrial Drying Process for 1000KG Meat Slices and Strips: Optimizing Quality with Heat Pump Technology

Introduction

Commercial production of dried meat slices and jerky requires precise dehydration technology to ensure food safety, extend shelf life, and maintain optimal texture and flavor. For large-scale operations processing 1000KG batches, selecting the appropriate drying method is crucial for product quality and operational efficiency. This technical analysis examines the industrial meat drying process using advanced Heat Pump Dryers compared to conventional Electric Heating Dryers.

Meat Drying and Processing Protocol

1. Raw Material Preparation

-

Selection & Trimming: Choose fresh, quality meat cuts; trim excess fat and connective tissue

-

Slicing & Sizing: Uniform slicing to 3-8mm thickness using industrial slicers

-

Marination & Curing: Immersion in seasoning solutions for 12-48 hours under refrigeration

2. Pre-drying Treatment

-

Surface Drying: Pat drying to remove excess moisture

-

Arrangement: Even spacing on drying trays for optimal air circulation

-

Sanitization: UV treatment of drying chamber before operation

3. Drying Process Parameters

-

Temperature Range: 55-68°C (131-154°F) for optimal protein preservation

-

Humidity Control:

-

Initial phase: 45-55% RH for surface drying

-

Main phase: 35-45% RH for internal moisture removal

-

Final phase: 25-35% RH for texture setting

-

-

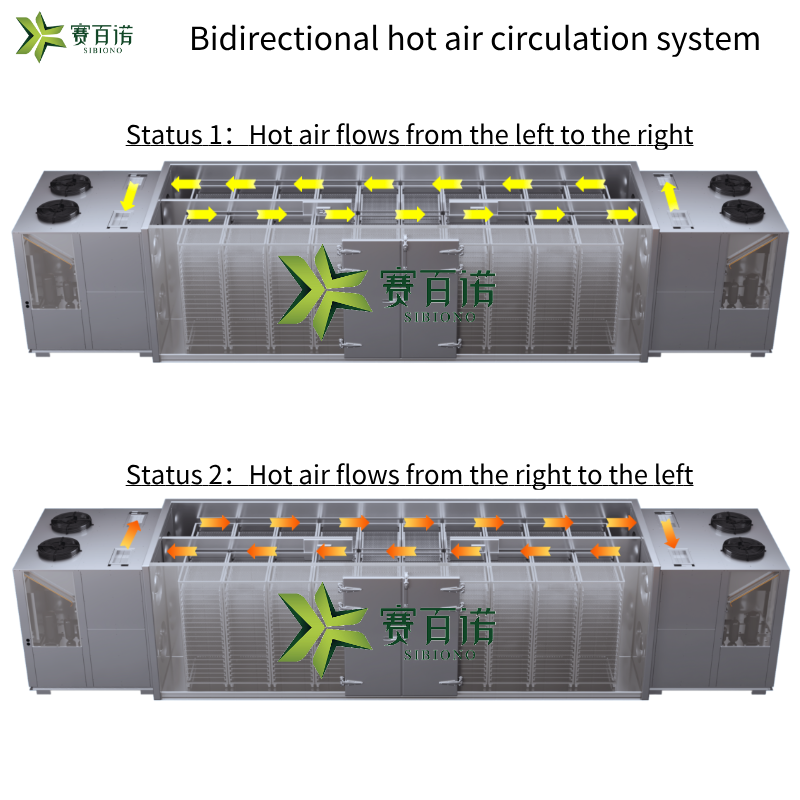

Airflow: Horizontal and vertical circulation for uniform drying

-

Processing Time: 6-12 hours depending on meat type and thickness

4. Post-drying Procedures

-

Cooling: Gradual temperature reduction to 20-25°C

-

Quality Inspection: Moisture content testing (target: 20-25% for jerky)

-

Packaging: Nitrogen flushing or vacuum sealing for preservation

Technology Comparison: Heat Pump vs Electric Dryers

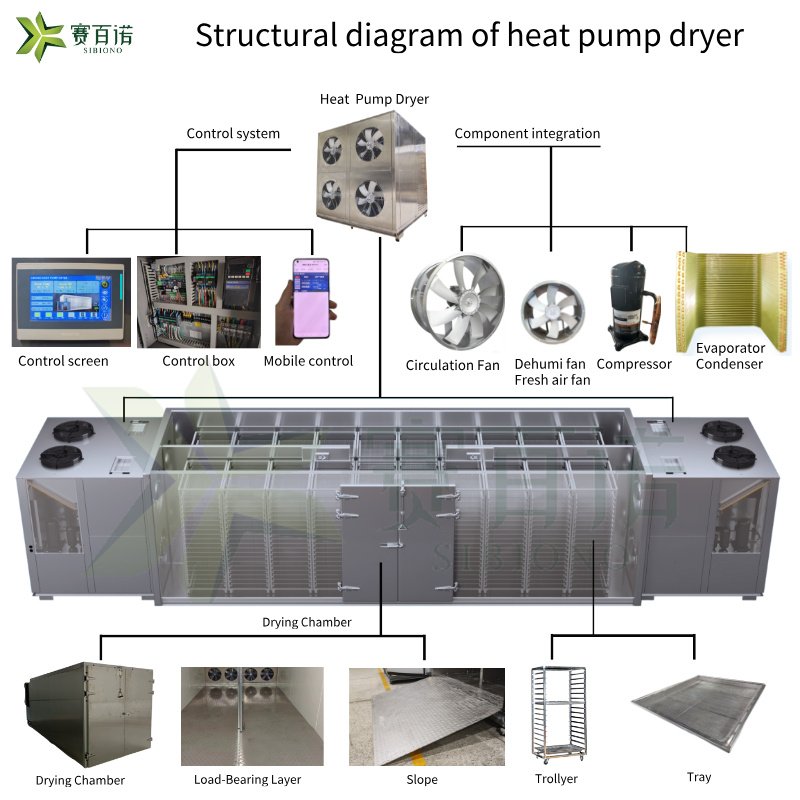

Heat Pump Dryer Advantages for Meat Processing

1. Superior Product Quality

-

Color Preservation: Precise temperature control prevents surface burning and discoloration

-

Texture Optimization: Even humidity distribution prevents case hardening

-

Flavor Retention: Gentle drying preserves natural meat flavors and marinade notes

-

Nutrient Conservation: Low-temperature operation maintains protein integrity

2. Operational Efficiency

-

Energy Savings: 50-65% reduced energy consumption versus electric dryers

-

Consistent Results: Automated humidity control ensures batch-to-batch uniformity

-

Reduced Shrinkage: Controlled drying minimizes product weight loss

-

Enhanced Safety: Integrated HACCP compliance features

3. Economic Benefits

-

Lower Operating Costs: Reduced energy consumption per kilogram

-

Higher Yield: Improved product quality reduces rejection rates

-

Less Maintenance: No heating element replacements required

Electric Heating Dryer Limitations

1. Quality Issues

-

Uneven drying causing texture variations

-

Surface burning and color degradation

-

Inconsistent final moisture content

-

Higher product rejection rates

2. Operational Drawbacks

-

High energy consumption (2.5-3.5 kWh per kg)

-

Frequent heating element maintenance

-

Poor humidity control leading to quality variations

-

Higher peak power demand

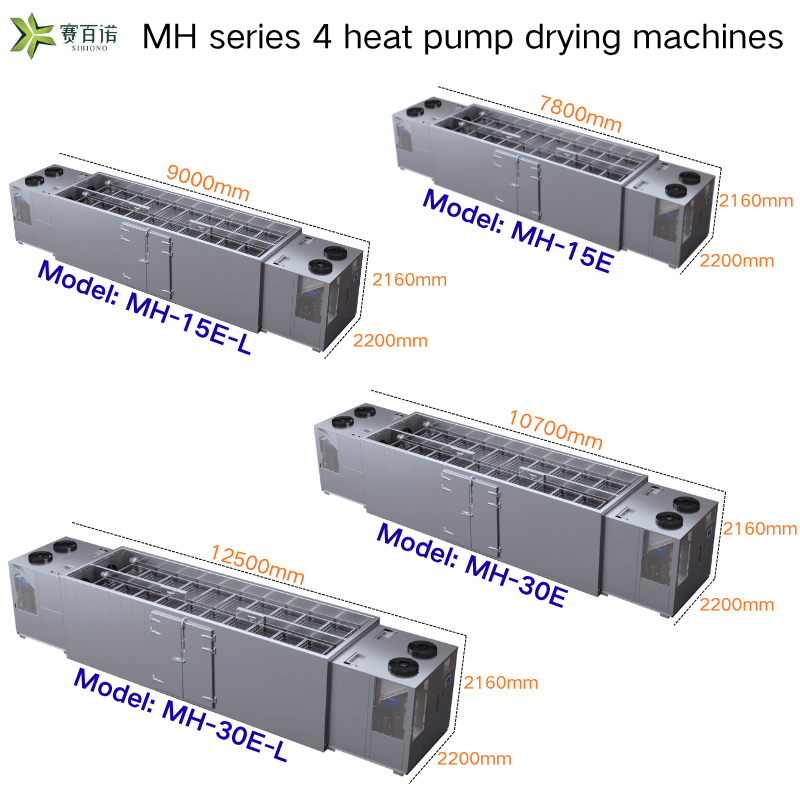

Technical Specifications – 1000KG Capacity

-

Drying Chamber Volume: 18-25m³

-

Temperature Range: 30-75°C (±1°C accuracy)

-

Dehumidification Capacity: 80-120L/hour

-

Power Requirements: 380V/3Phase/60A

-

Control System: PLC with recipe memory and remote monitoring