Drying and Processing of 1000KG Figs: Enhancing Quality with Advanced Technology

Introduction

Figs are a delicate, high-value fruit whose quality must be meticulously preserved during drying. For commercial operations processing 1000KG batches, selecting the right drying technology is critical to maximizing shelf life, preserving their unique texture and flavor, and ensuring profitability. This article outlines the industrial fig drying process and provides a detailed comparison between the efficiency of Heat Pump Dryers and the conventional method of Electric Heating Dryers.

Industrial Fig Drying and Processing Workflow

-

Selection and Sorting: High-quality drying starts with premium fresh figs. Fruits are carefully sorted to select fully ripe but firm figs, free from bruises and splits.

-

Cleaning and Washing: Figs are gently washed with soft sprays or in immersion washers to remove dirt and any field residues without damaging their delicate skin.

-

Pre-treatment (Optional):

-

Blanching: Dipping figs in hot water or steaming them briefly helps to clean the skin more thoroughly, soften it for faster drying, and destroy surface enzymes.

-

Puncturing/Dipping: Some processors lightly puncture the fig skin or dip them in a light food-grade oil solution to prevent skin rupture and control the drying rate from the inside out.

-

-

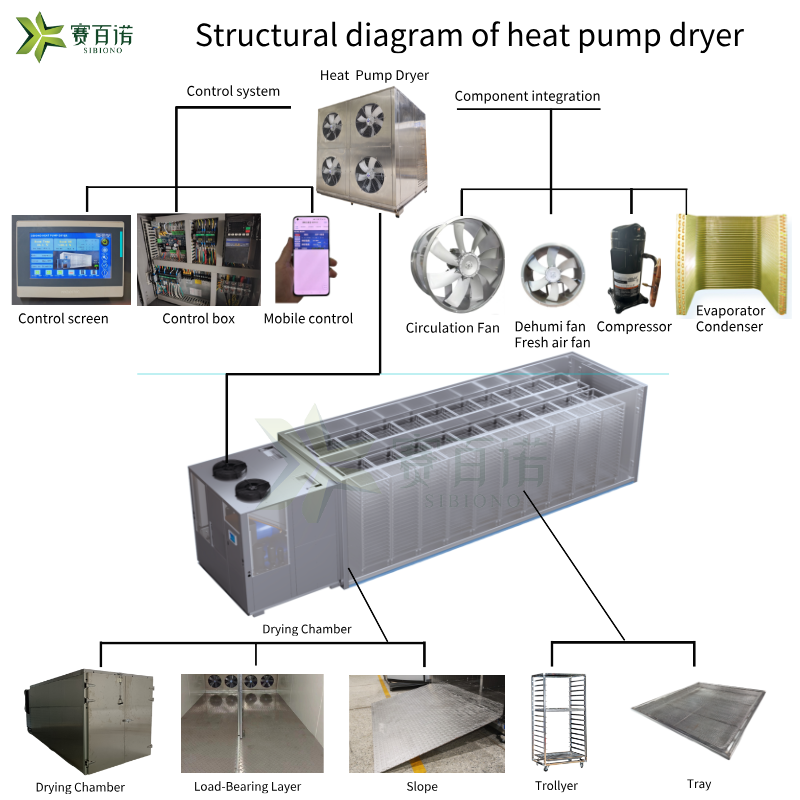

Loading and Drying: Figs are loaded in a single layer onto trays. They are then dried in the 1000KG capacity dryer. The process requires low temperatures (typically 50-65°C / 122-149°F) and controlled humidity to dry the moisture-rich interior without hardening the exterior.

-

Cooling and Conditioning: After drying to a pliable, leathery texture with a moisture content of around 15-20%, the figs are cooled. They are often conditioned in bins to allow residual moisture to equalize evenly across all fruits.

-

Packaging: The final step involves packaging the dried figs in vacuum-sealed or modified atmosphere packaging to maintain their soft texture and prevent spoilage.

Technology Comparison: Heat Pump Dryer vs. Electric Heating Dryer

For a 1000KG operation, the drying method chosen has a direct and significant impact on both the quality of the final product and operational costs.

Heat Pump Dryer: The Superior Choice for Delicate Fruits

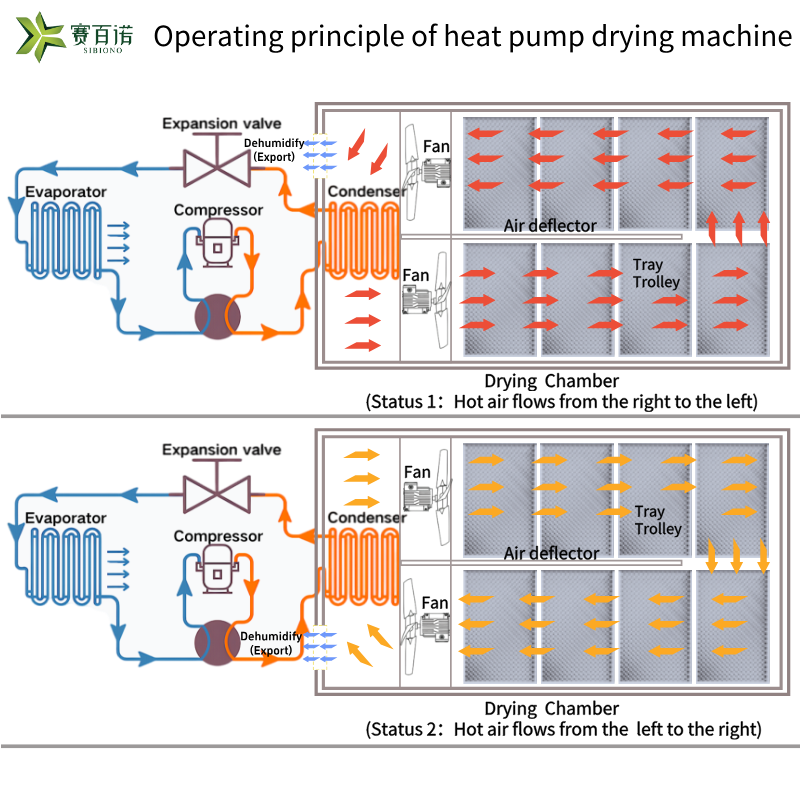

A heat pump dryer uses a refrigerant cycle to absorb ambient heat and transfer it into the drying chamber, simultaneously controlling temperature and dehumidifying the air.

-

Optimal Energy Efficiency: By recycling heat within a closed system, heat pump dryers can reduce energy consumption by 50-70% compared to electric dryers. This leads to dramatically lower operating costs, a crucial factor for high-volume processing.

-

Exceptional Quality Preservation: Precise control over temperature and humidity is vital for figs. Heat pump technology provides a gentle, even drying environment that prevents the skin from hardening too quickly and trapping moisture inside (case-hardening). This results in a perfectly chewy texture, preserves the natural golden to deep brown color, and locks in the fig’s characteristic honey-like sweetness.

-

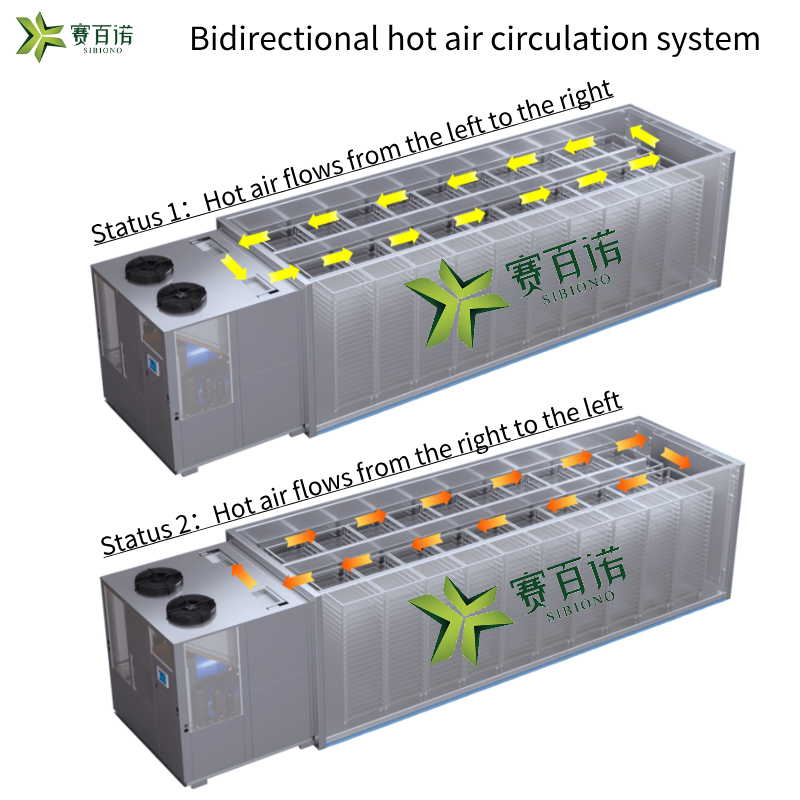

Gentle and Uniform Drying: The consistent, low-temperature drying ensures that every fig in the 1000KG batch is dried evenly, eliminating burnt sugars or uneven moisture levels that can lead to spoilage.

-

Eco-Friendly Operation: The significant reduction in electricity use translates to a lower carbon footprint, supporting sustainable production practices.

Electric Heating Dryer: The Conventional, Higher-Risk Method

Electric dryers generate heat directly through electrical resistance elements, functioning like a large industrial oven.

-

High Operational Costs: The direct conversion of electricity to heat is inefficient for moisture removal, leading to substantially higher energy bills. For a 1000KG batch, this inefficiency quickly erodes profit margins.

-

Significant Quality Risks: Electric dryers often lack precise humidity control. The intense, dry heat can easily cause case-hardening, resulting in a tough exterior and a sticky, under-dried, or fermented interior. It can also cause scorching, giving the figs a bitter taste and an unappealingly dark color.

-

Simplicity and Lower Initial Cost: The main advantage is a simpler mechanical system and a potentially lower upfront purchase price. However, this cost saving is quickly offset by higher long-term energy expenses and the risk of producing a lower-quality product that sells for a lesser price.

Conclusion: The Clear Advantage of a 1000KG Heat Pump Dryer for Figs

For any commercial fig processor aiming for the premium market, the 1000KG Heat Pump Dryer is the definitive investment. It transforms the drying process from a high-cost, high-risk operation into an efficient, reliable, and quality-focused one. The ability to consistently produce superior, high-value dried figs with perfect texture and flavor, combined with drastically lower running costs, ensures maximum return on investment and a strong competitive advantage.