Industrial Drying Process for 2000KG Bamboo Stick Incense: Precision Drying with Heat Pump Technology

Introduction

The production of high-quality bamboo stick incense requires meticulous drying conditions to prevent cracking, maintain fragrance integrity, and ensure perfect combustion properties. For industrial-scale operations processing 2000KG batches, selecting appropriate drying technology is crucial for manufacturing premium incense products that meet religious and commercial standards. This technical analysis examines the industrial incense drying process using advanced Heat Pump Dryers compared to conventional Electric Heating Dryers.

Bamboo Stick Incense Drying Protocol

1. Raw Material Preparation

-

Bamboo Stick Treatment: Pre-dried bamboo sticks of uniform length and diameter

-

Incense Paste Application: Even coating of fragrant mixture onto bamboo sticks

-

Quality Inspection: Verification of coating uniformity and thickness

-

Loading Configuration: Strategic hanging arrangement for optimal air circulation

2. Multi-Stage Drying Parameters

-

Phase 1 (Initial Setting – 1-3 hours):

-

Temperature: 50-55°C

-

Humidity: 55-70% RH

-

Purpose: Gradual surface moisture removal to prevent cracking

-

-

Phase 2 (Core Drying – 3-6 hours):

-

Temperature:55-60°C

-

Humidity: 40-50% RH

-

Purpose: Internal moisture migration and shape stabilization

-

-

Phase 3 (Conditioning – 6-11 hours):

-

Temperature: 60-63°C

-

Humidity: 25-28% RH

-

Purpose: Stress relief and moisture equilibrium

-

3. Quality Control Standards

-

Moisture Content: 8-10% final moisture level

-

Visual Inspection: No cracks, bends, or surface defects

-

Fragrance Testing: Consistent aroma profile maintenance

-

Combustion Quality: Even burning without sparking or extinguishing

Technology Comparison: Heat Pump vs Electric Dryers

Heat Pump Dryer Advantages for Incense Production

1. Superior Product Quality

-

Crack Prevention: Controlled humidity eliminates bamboo splitting

-

Shape Preservation: Prevents bending and deformation

-

Fragrance Retention: Maintains essential oil integrity and scent profile

-

Consistent Combustion: Uniform drying ensures reliable burning quality

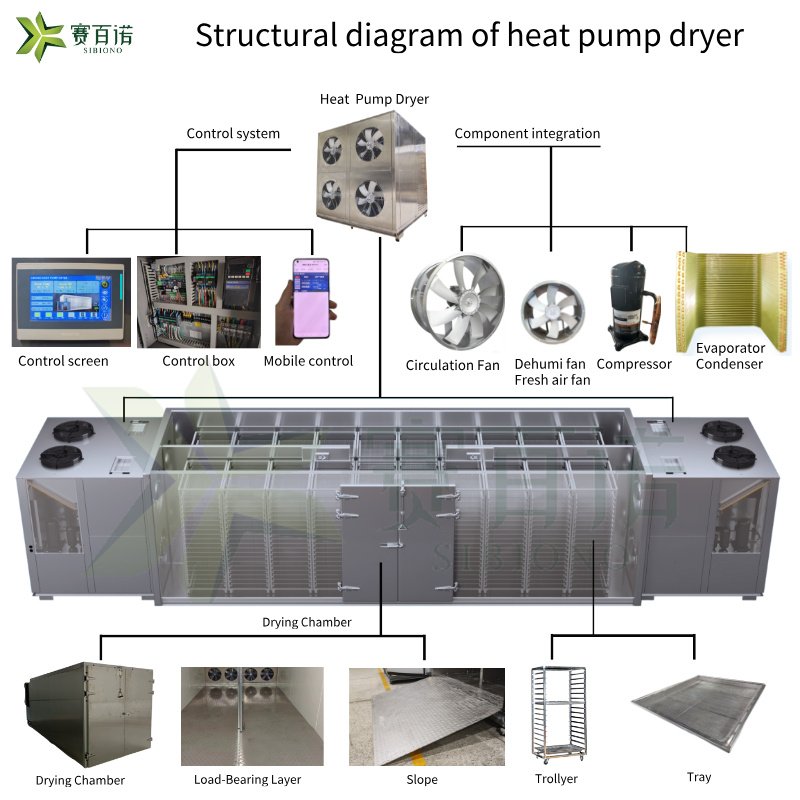

2. Technical Excellence

-

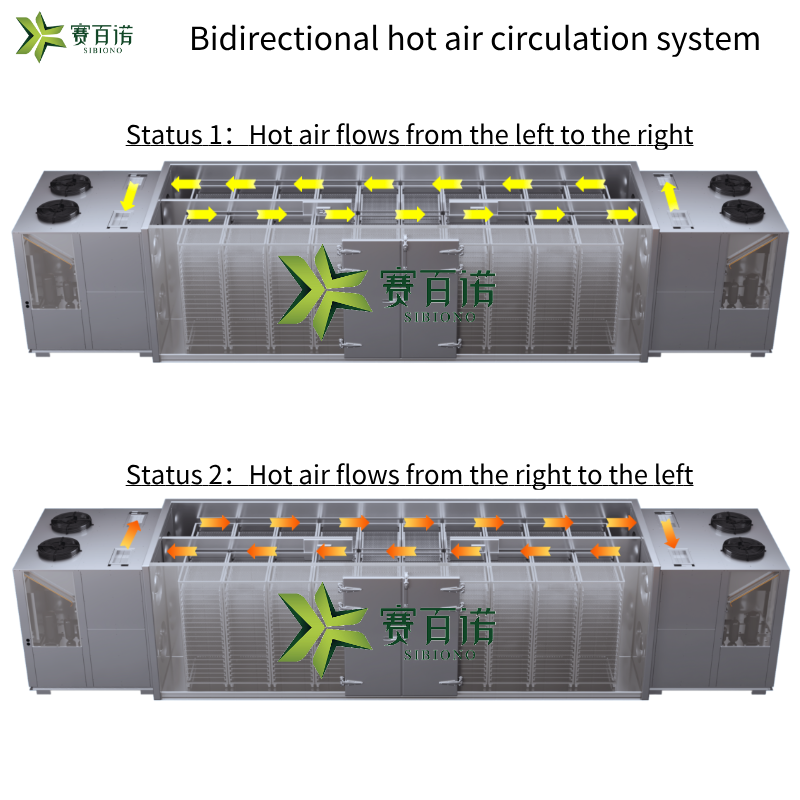

Precise Humidity Control: ±2% RH accuracy for perfect drying conditions

-

Temperature Stability: ±0.5°C maintenance throughout all phases

-

Energy Efficiency: 65-75% reduction in energy consumption

-

Automated Programming: Customizable drying cycles for different formulations

3. Economic Benefits

-

Reduced Waste: Minimal product rejection due to cracking

-

Energy Savings: Significant reduction in operating costs

-

Higher Throughput: Faster drying cycles with better quality

-

Lower Maintenance: Reduced component replacement frequency

Electric Heating Dryer Limitations

1. Quality Issues

-

High incidence of cracking and splitting

-

Uneven drying causing combustion problems

-

Fragrance loss due to excessive temperatures

-

Shape deformation from rapid moisture removal

2. Operational Challenges

-

High energy consumption (4.0-5.0 kWh per kg)

-

Inadequate humidity control capabilities

-

Temperature inconsistencies affecting batch quality

-

Frequent maintenance requirements

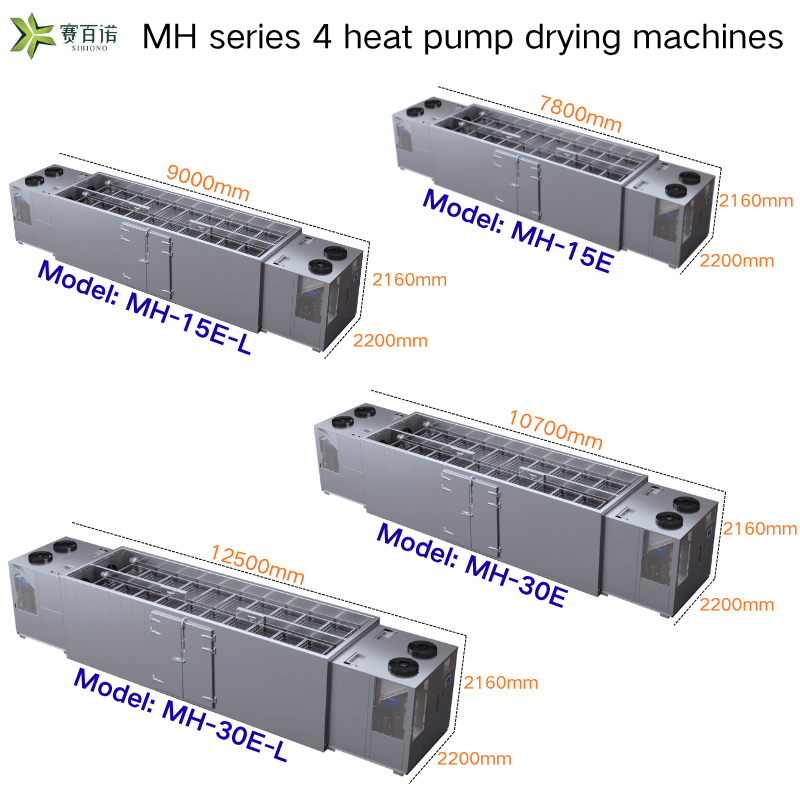

Technical Specifications – 2000KG Capacity

-

Drying Chamber Volume: 50-65m³

-

Temperature Range: 25-55°C (±0.5°C accuracy)

-

Humidity Control: 35-75% RH (±2% precision)

-

Drying Time: 34-48 hours depending on paste thickness

-

Power Requirements: 380V/3Phase/85-110A

-

Control System: Advanced PLC with recipe storage

Conclusion

The 2000KG Heat Pump Dryer provides the ultimate solution for commercial bamboo stick incense production, delivering exceptional product quality, operational efficiency, and cost-effectiveness. While electric dryers may appear cost-effective initially, the heat pump technology’s precise environmental control and energy efficiency make it indispensable for manufacturers producing premium incense products. The technology’s ability to prevent cracking while maintaining fragrance integrity ensures superior return on investment for incense manufacturers targeting quality-conscious markets where product appearance and performance are paramount.