Industrial Drying Process for 1000KG Edible Mushrooms (Shiitake): Optimizing Quality with Heat Pump Technology

Introduction

Shiitake mushroom drying requires precise temperature and humidity control to develop their characteristic umami flavor, preserve nutritional value, and achieve the desired texture. For commercial operations processing 1000KG batches, maintaining optimal drying conditions is crucial for producing premium dried mushrooms that meet international quality standards. This technical analysis examines the industrial mushroom drying process using advanced Heat Pump Dryers compared to conventional Electric Heating Dryers.

Shiitake Mushroom Drying Protocol

1. Pre-drying Preparation

-

Selection & Grading: Fresh shiitake mushrooms with 80-90% maturity, uniform size

-

Cleaning: Gentle air blowing or soft brushing to remove substrate and impurities

-

Arrangement: Placement with adequate spacing between mushrooms

-

Sorting: Separation by cap size and thickness for uniform drying

2. Multi-Stage Drying Parameters

-

Phase 1 (Initial – 2-3 hours):

-

Temperature: 35-40°C

-

Humidity: 70-75% RH

-

Purpose: Gentle initial moisture removal

-

-

Phase 2 (Main – 8-10 hours):

-

Temperature: 45-55°C

-

Humidity: 60-65% RH

-

Purpose: Internal moisture migration and flavor development

-

-

Phase 3 (Final – 4-6 hours):

-

Temperature: 55-60°C

-

Humidity: 45-50% RH

-

Purpose: Final drying and texture formation

-

-

Phase 4 (Conditioning – 1-2 hours):

-

Temperature: 40-45°C

-

Humidity: 35-40% RH

-

Purpose: Moisture equalization

-

3. Quality Control Standards

-

Moisture Content: 12-13% final moisture level

-

Appearance: Natural brown color with intact caps

-

Texture: Crisp but not brittle

-

Aroma: Strong umami fragrance development

Technology Comparison: Heat Pump vs Electric Dryers

Heat Pump Dryer Advantages for Mushroom Processing

1. Superior Quality Preservation

-

Flavor Enhancement: Develops full umami flavor through controlled drying

-

Color Retention: Maintains natural brown color without darkening

-

Texture Perfection: Achieves ideal crispness without brittleness

-

Nutritional Conservation: Preserves lentinan and other bioactive compounds

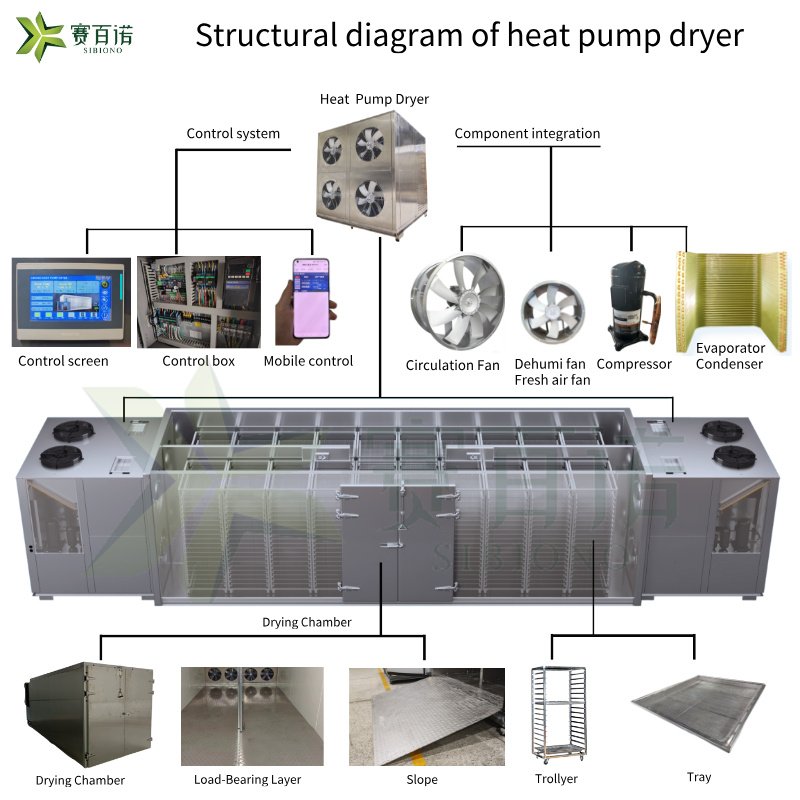

2. Technical Superiority

-

Precise Humidity Control: ±3% RH accuracy for perfect drying conditions

-

Temperature Precision: ±1°C maintenance throughout all phases

-

Energy Efficiency: 60-70% reduction in energy consumption

-

Automated Operation: Programmable multi-stage drying cycles

3. Economic Benefits

-

Higher Product Value: Premium quality commands 30-50% higher prices

-

Reduced Operating Costs: Significant energy savings

-

Increased Yield: Minimal breakage and quality rejection

-

Consistent Results: Batch-to-batch uniformity

Electric Heating Dryer Limitations

1. Quality Issues

-

Case hardening preventing proper internal drying

-

Color darkening and uneven drying

-

Loss of volatile aroma compounds

-

Brittle texture leading to breakage

2. Operational Challenges

-

High energy consumption (3.0-4.0 kWh per kg)

-

Manual humidity control requirements

-

Temperature fluctuations affecting quality

-

Higher maintenance costs

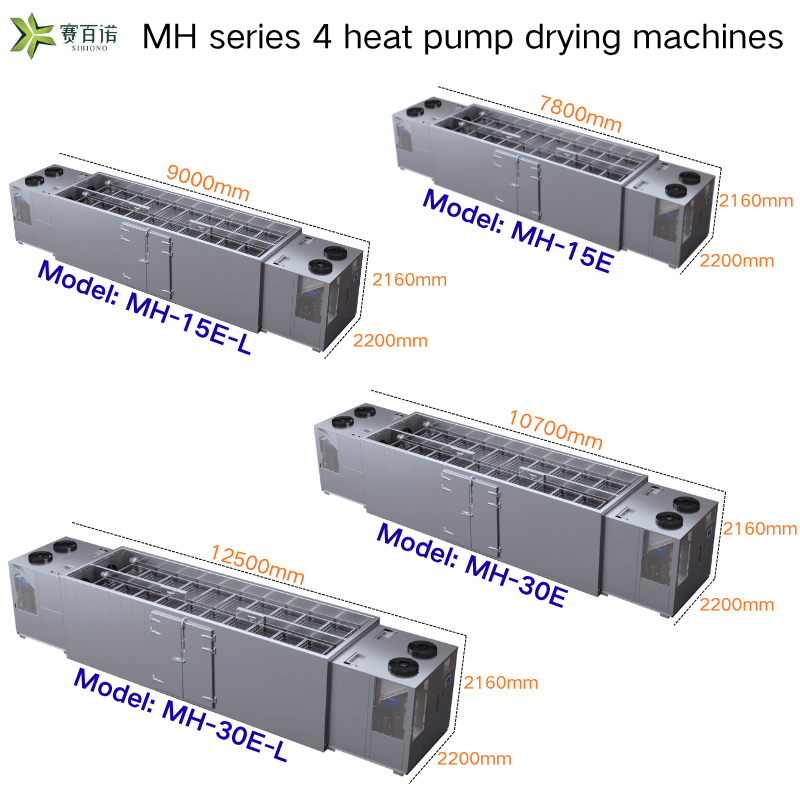

Technical Specifications – 1000KG Capacity

-

Drying Chamber Volume: 20-28m³

-

Temperature Range: 30-65°C (±1°C accuracy)

-

Humidity Control: 30-80% RH (±3% precision)

-

Drying Time: 15-21 hours depending on mushroom size

-

Power Requirements: 380V/3Phase/45-60A

-

Control System: PLC with customizable drying programs

Conclusion

The 1000KG Heat Pump Dryer represents the optimal solution for commercial shiitake mushroom processing, delivering exceptional product quality, operational efficiency, and cost-effectiveness. While electric dryers may offer simpler operation, the heat pump technology’s precise environmental control and energy efficiency make it essential for producing premium dried mushrooms that meet the highest quality standards. The technology’s ability to enhance natural umami flavor while significantly reducing operational costs ensures excellent return on investment for mushroom processors targeting premium markets where quality and consistency are paramount.