Industrial Drying Process for 800-1000KG Traditional Sausages (Lap Cheong): Advanced Heat Pump Technology

Introduction

The production of traditional Chinese sausages (lap cheong) requires precise drying conditions to develop their characteristic flavor, texture, and preservation qualities. For commercial operations processing 800-1000KG batches, maintaining optimal temperature and humidity levels is crucial for achieving authentic quality while ensuring food safety. This technical analysis examines the industrial sausage drying process using advanced Heat Pump Dryers compared to conventional methods.

Traditional Sausage Drying Protocol

1. Raw Material Preparation

-

Meat Selection: Premium pork (70% lean, 30% fat) and traditional seasonings

-

Casings Preparation: Natural hog casings cleaning and preparation

-

Mixing & Stuffing: Uniform mixing of ingredients and mechanical stuffing

-

Pricking & Stringing: Air bubble removal and hanging preparation

2. Pre-drying Treatment

-

Initial Setting: 2-4 hours at room temperature for surface drying

-

Arrangement: Uniform spacing on drying racks for optimal air circulation

-

Sanitation: UV treatment of drying chamber

3. Multi-Stage Drying Parameters

-

Phase 1 (0-7 hours):

-

Temperature: 60-65°C

-

Humidity: 60-68% RH

-

Purpose: Initial moisture removal without case hardening

-

-

Phase 2 (7-20 hours):

-

Temperature: 52-58°C

-

Humidity: 50-55% RH

-

Purpose: Flavor development and fat stabilization

-

-

Phase 3 (20-50 hours):

-

Temperature: 45-50°C

-

Humidity: 45-50% RH

-

Purpose: Final drying and texture formation

-

4. Quality Control & Packaging

-

Moisture Testing: Target 25-30% final moisture content

-

Color Assessment: Uniform reddish-brown appearance

-

Texture Evaluation: Firm but pliable consistency

-

Vacuum Packaging: Oxygen-free packaging for preservation

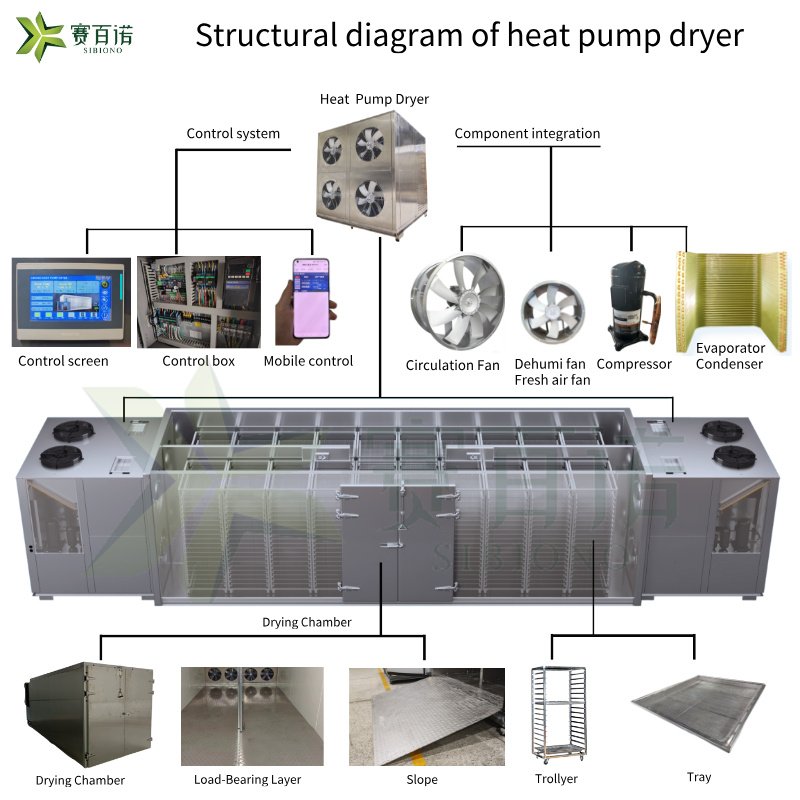

Technology Comparison: Heat Pump vs Traditional Dryers

Heat Pump Dryer Advantages for Sausage Production

1. Quality Excellence

-

Flavor Development: Precise temperature control enhances traditional flavor profile

-

Color Preservation: Prevents discoloration and maintains appealing appearance

-

Texture Perfection: Even drying prevents case hardening and ensures ideal chewiness

-

Fat Retention: Controlled conditions prevent fat separation and oxidation

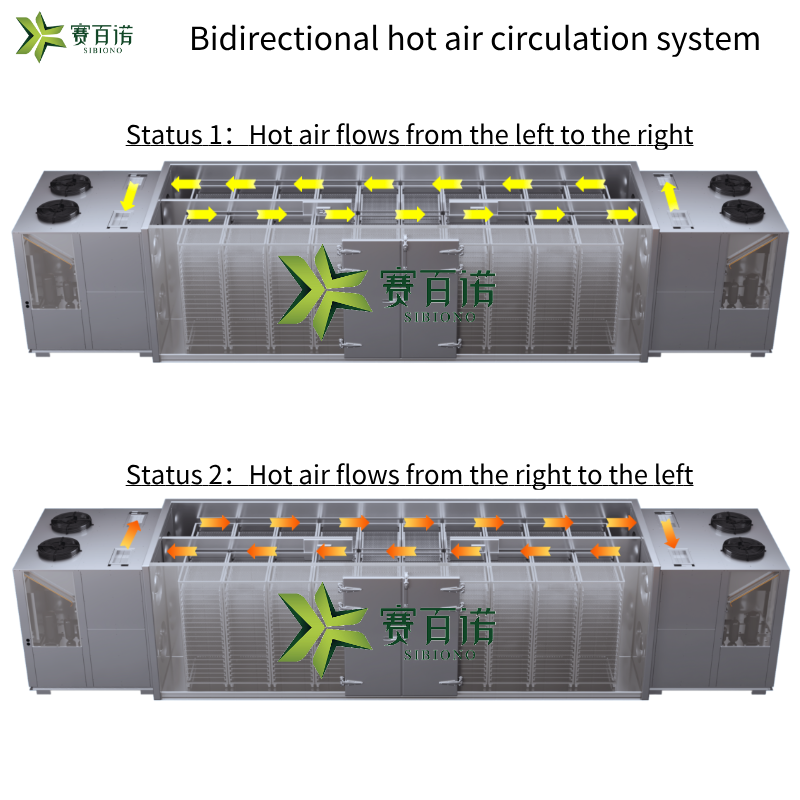

2. Technical Superiority

-

Multi-Stage Programming: Automated phase transitions for consistent results

-

Precise Humidity Control: ±3% RH accuracy throughout drying process

-

Energy Efficiency: 50-60% energy savings compared to electric dryers

-

Hygienic Operation: Closed-loop system prevents contamination

3. Economic Benefits

-

Reduced Shrinkage: Controlled drying minimizes weight loss

-

Higher Yield: Consistent quality reduces rejection rates

-

Labor Savings: Automated operation reduces manual monitoring

-

Year-Round Production: Weather-independent operation

Electric Heating Dryer Limitations

1. Quality Issues

-

Uneven drying leading to texture variations

-

Case hardening causing internal spoilage risk

-

Color inconsistency and fat melting

-

Flavor loss due to excessive temperatures

2. Operational Challenges

-

High energy consumption (2.8-3.5 kWh per kg)

-

Manual humidity control requirements

-

Temperature fluctuations affecting quality

-

Higher maintenance costs

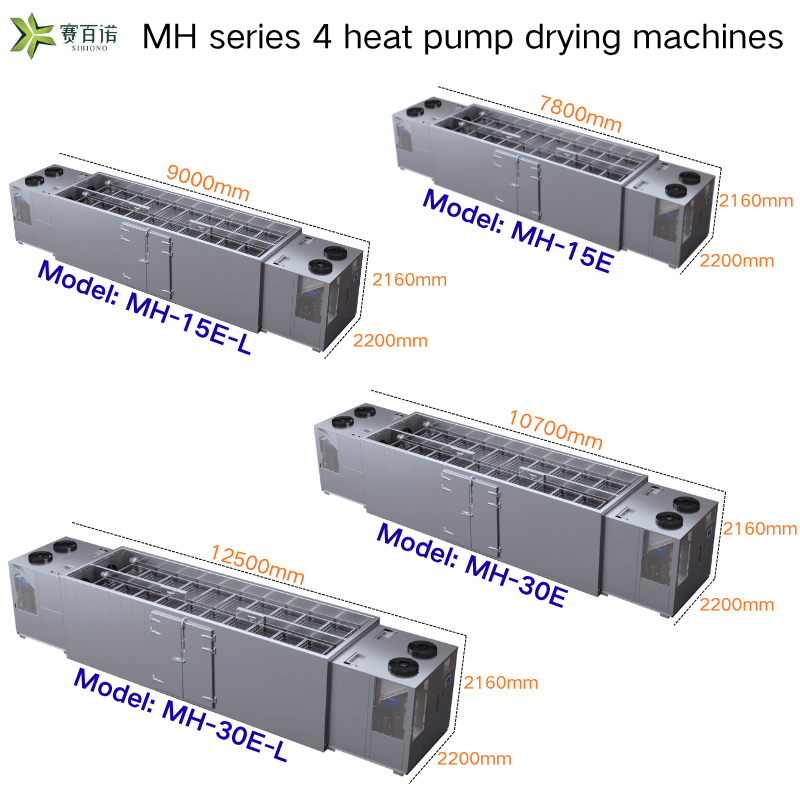

Technical Specifications – 800-1000KG Capacity

-

Drying Chamber Volume: 25-35m³

-

Temperature Range: 40-65°C (±1°C accuracy)

-

Humidity Control: 40-70% RH (±3% precision)

-

Drying Cycle: 5-7 days depending on specifications

-

Power Requirements: 380V/3Phase/50-65A

-

Control System: PLC with recipe memory and remote monitoring

Conclusion

The 800-1000KG Heat Pump Dryer represents the ideal solution for commercial traditional sausage production, delivering superior product quality, operational efficiency, and cost-effectiveness. While electric dryers may offer simpler operation, the heat pump technology’s precise environmental control and energy efficiency make it essential for producing premium quality lap cheong that meets traditional standards and modern food safety requirements. The technology’s ability to maintain consistent quality while reducing operational costs ensures excellent return on investment for sausage manufacturers competing in both domestic and international markets.