Drying and Processing of 1000KG Cactus Pads (Nopales): A Guide to Efficient Dehydration

Introduction

The drying of cactus pads, or Nopales, is an efficient way to create valuable products for the animal feed and food industries, extending shelf life and concentrating nutrients. For large-scale operations processing 1000KG batches, selecting the right drying technology is critical to preserving the nutritional integrity and quality of the final product. This article details the industrial cactus drying process and compares the advanced technology of Heat Pump Dryers with conventional Electric Heating Dryers.

Industrial Cactus Drying and Processing Workflow

-

Harvesting and Selection: Mature, healthy cactus pads (Nopales) are harvested. Pads with signs of disease or severe damage are discarded.

-

Spine Removal and Cleaning: The sharp spines (glochids) are meticulously removed using mechanical brushes or singeing. The pads are then thoroughly washed to remove dirt and debris.

-

Slicing/Dicing: The cleaned pads are sliced into strips or diced into uniform pieces to increase the surface area for faster and more consistent drying.

-

Blanching (Optional for Food Grade): For food-grade products, blanching in hot water or steam is often performed. This step helps to:

-

Reduce the characteristic mucilage (slimy texture).

-

Set the green color.

-

Destroy enzymes that can cause spoilage.

-

-

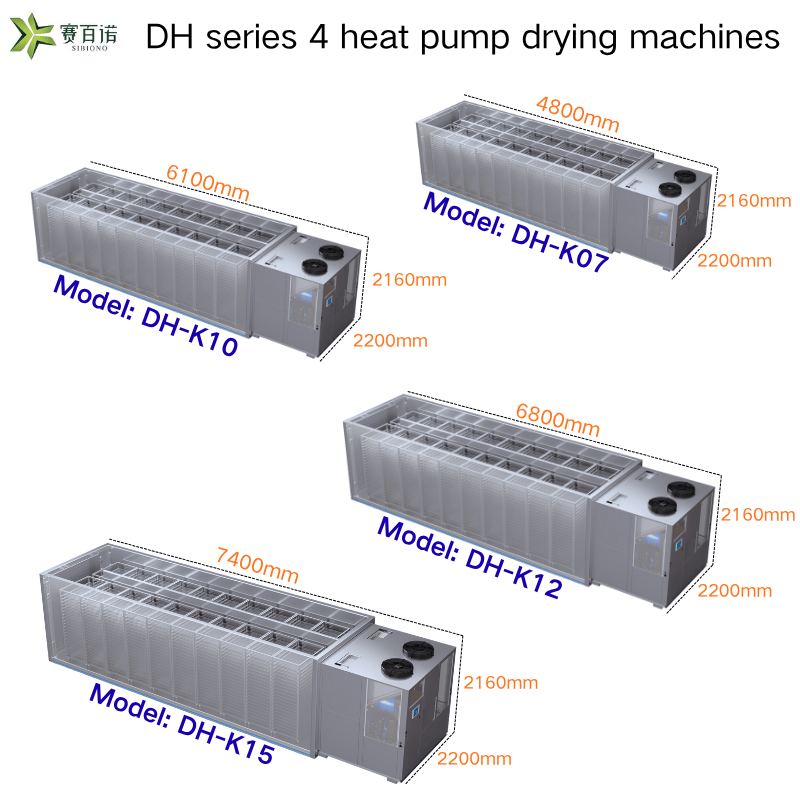

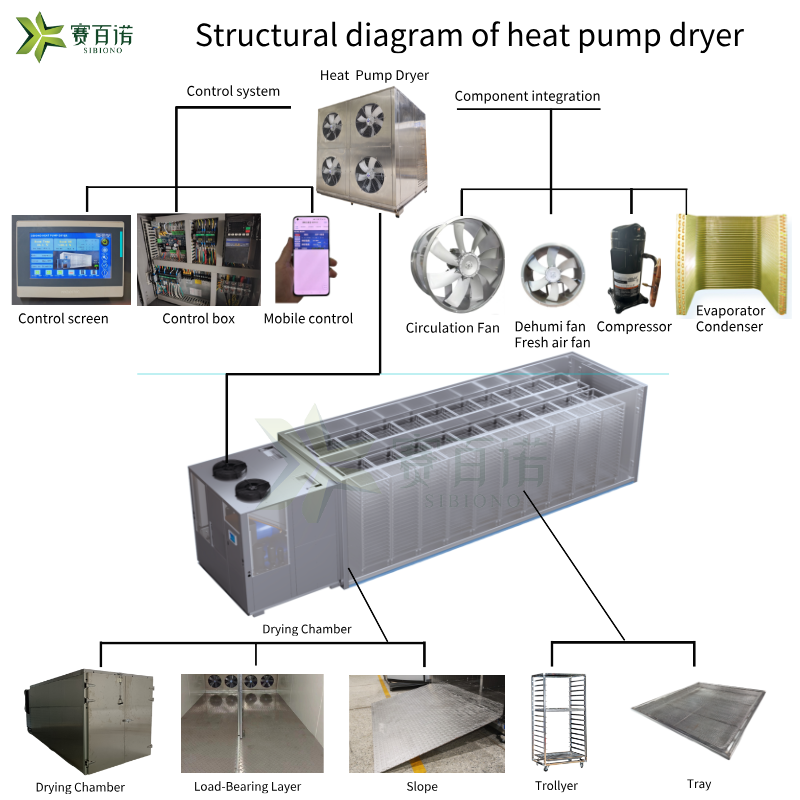

Loading and Drying: The prepared cactus pieces are evenly spread on trays and loaded into the 1000KG capacity dryer. Drying is typically carried out at a moderate temperature range of 55°C to 70°C (131°F – 158°F). Effective moisture removal is crucial due to the high water content of cactus.

-

Cooling and Packaging: After drying to a target moisture content of around 10-12%, the cactus pieces are cooled to ambient temperature. The final product is packaged in durable, moisture-proof bags for storage or sale, often as animal feed or a food ingredient.

Technology Comparison: Heat Pump Dryer vs. Electric Heating Dryer

For a 1000KG cactus operation, the drying method directly impacts nutrient retention, energy costs, and production efficiency.

Heat Pump Dryer: The Efficient and High-Quality Solution

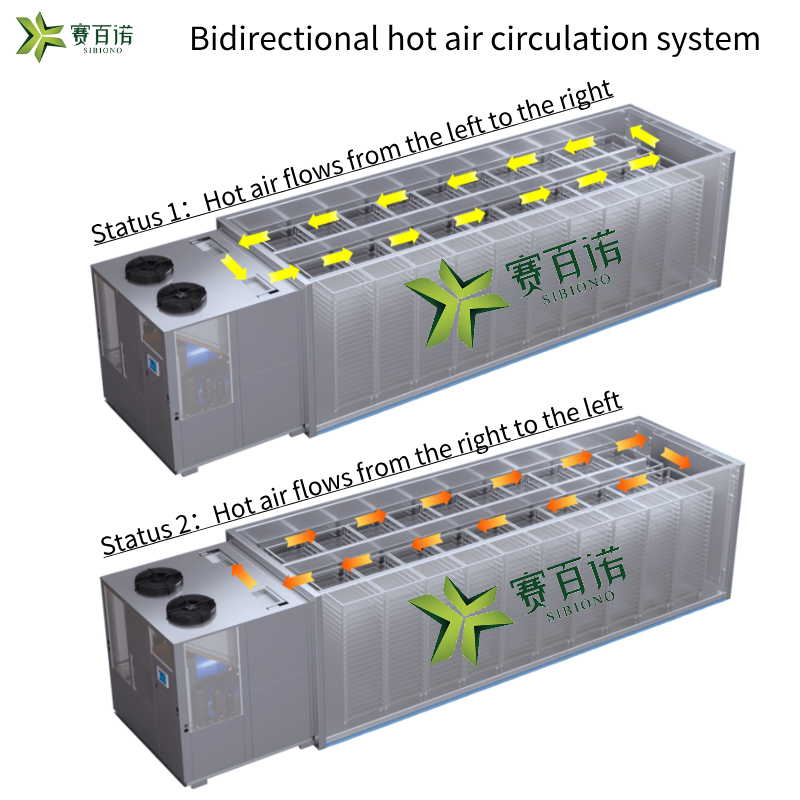

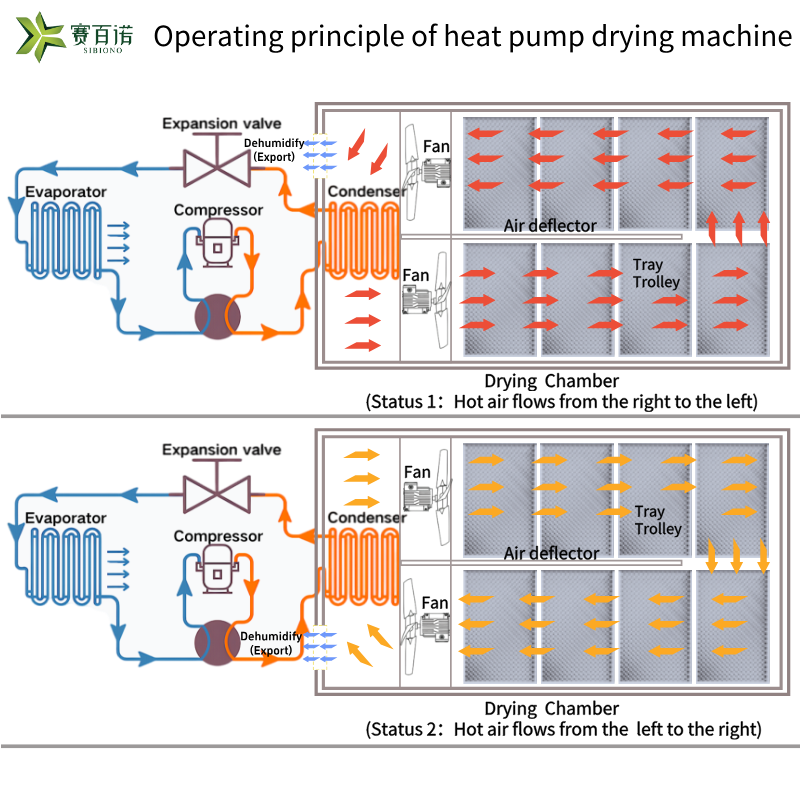

A heat pump dryer uses a refrigeration cycle to transfer heat, providing precise control over both temperature and humidity in a closed-loop system.

-

Superior Energy Efficiency: By recycling thermal energy, heat pump dryers can achieve energy savings of 50-70% compared to electric dryers. This drastically reduces the cost of removing the high water content from cactus, making the process highly economical.

-

Excellent Nutrient Preservation: The gentle, controlled drying environment prevents the degradation of heat-sensitive vitamins and nutrients present in cactus. It effectively removes moisture without scorching, preserving the nutritional value essential for animal feed and food products.

-

Uniform and Controlled Drying: Precise humidity control prevents case-hardening, ensuring moisture is evenly removed from the entire 1000KG batch. This results in a consistent, stable product with a lower risk of microbial growth post-drying.

-

Environmentally Friendly: Lower energy consumption translates to a smaller carbon footprint, supporting sustainable agricultural processing.

Electric Heating Dryer: The Conventional, Less Efficient Method

Electric dryers generate heat directly through electrical resistance elements, using dry, intense heat for dehydration.

-

High Operational Costs: The direct conversion of electricity to heat is inefficient for evaporating large volumes of water, leading to very high energy bills for a 1000KG cactus batch.

-

Risk of Nutrient Loss and Quality Damage: The high, less controlled temperatures can easily degrade vitamins and cause the natural sugars in the cactus to caramelize on the surface. This can lead to a darkened color, a burnt taste, and a less nutritious final product.

-

Uneven Drying: Without active dehumidification, electric dryers can cause the outside of the cactus pieces to harden quickly while the inside remains moist. This uneven drying can lead to spoilage and mold during storage.

-

Simplicity and Lower Initial Cost: The main advantage is a simpler mechanical design and a potentially lower upfront cost. However, this is offset by significantly higher long-term operating expenses and a lower-quality product.

Conclusion: The Strategic Advantage of a 1000KG Heat Pump Dryer for Cactus

For any commercial operation focused on drying cactus for feed or food, the 1000KG Heat Pump Dryer is the most intelligent investment. It is specifically engineered to handle the high-moisture content of cactus efficiently and economically. By preserving vital nutrients and ensuring a uniform, high-quality product, the heat pump dryer maximizes the value of your raw material while minimizing operational costs through unmatched energy efficiency. This technology is essential for building a profitable and sustainable cactus processing business.