Drying and Processing of 1000KG Rose Petals: Preserving Color, Fragrance, and Value

Introduction

The drying of rose petals is a delicate process crucial for markets like herbal tea, cosmetics, and culinary arts. For commercial operations processing 1000KG batches, preserving the petal’s vibrant color, potent fragrance, and organic integrity is paramount to achieving a high-value product. This article details the industrial rose petal drying workflow and provides a critical comparison between the gentle efficiency of Heat Pump Dryers and the harshness of traditional Electric Heating Dryers.

Industrial Rose Petal Drying and Processing Workflow

-

Harvesting and Selection: Roses are harvested at their peak, typically early morning when their essential oil content is highest. Only fresh, blemish-free, and fully bloomed petals are selected for drying.

-

Gentle Cleaning: The petals are gently air-washed or lightly rinsed to remove dust and impurities. Care is taken to avoid bruising or damaging the delicate structures that contain the fragrance and color.

-

Pre-treatment (Optional): For some applications, petals may be treated with food-grade agents to help set color, though many premium processors rely solely on optimal drying conditions to maintain a natural state.

-

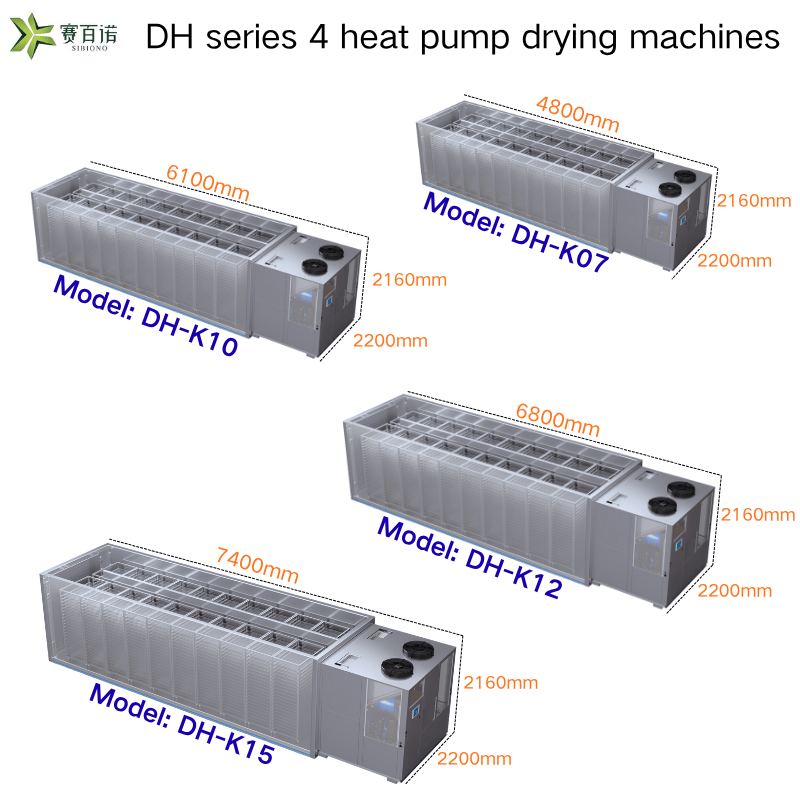

Loading and Drying: Petals are spread in a thin, single layer on drying trays to ensure optimal air circulation. They are then dried in the 1000KG capacity dryer at a very low and controlled temperature, typically between 35°C and 45°C (95°F – 113°F). Precise humidity control is absolutely critical.

-

Moisture Equilibrium and Packaging: After drying, the petals are conditioned in a controlled environment to allow residual moisture to equalize, ensuring no mold growth during storage. The final product is packaged in vacuum-sealed or dark, airtight containers to protect it from light, moisture, and oxygen, which degrade color and fragrance.

Technology Comparison: Heat Pump Dryer vs. Electric Heating Dryer

For a 1000KG rose petal operation, the choice of dryer is the single most important factor in determining the quality and value of the final product.

Heat Pump Dryer: The Gold Standard for Delicate Botanicals

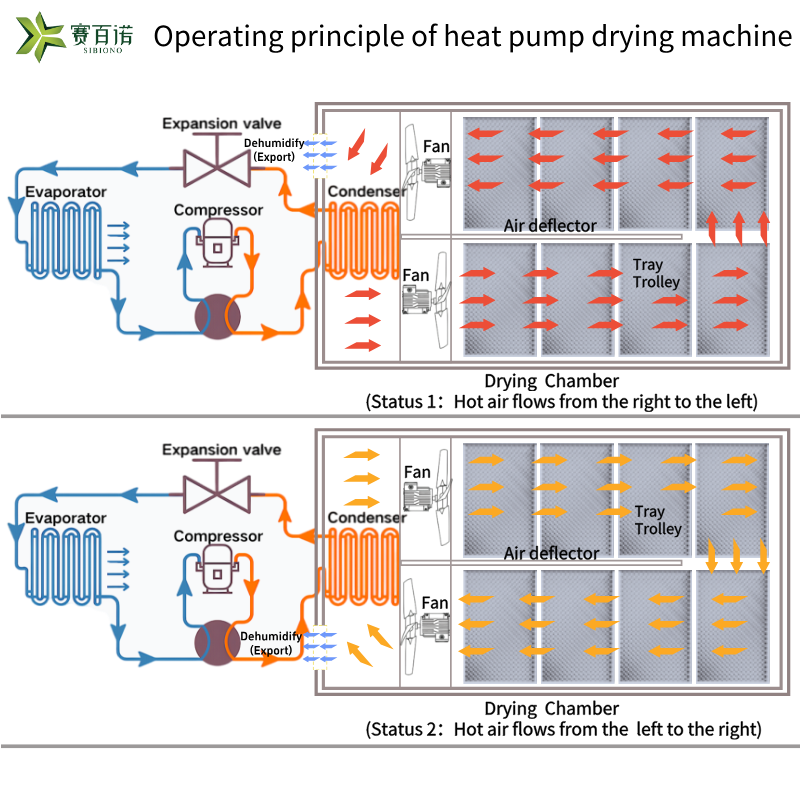

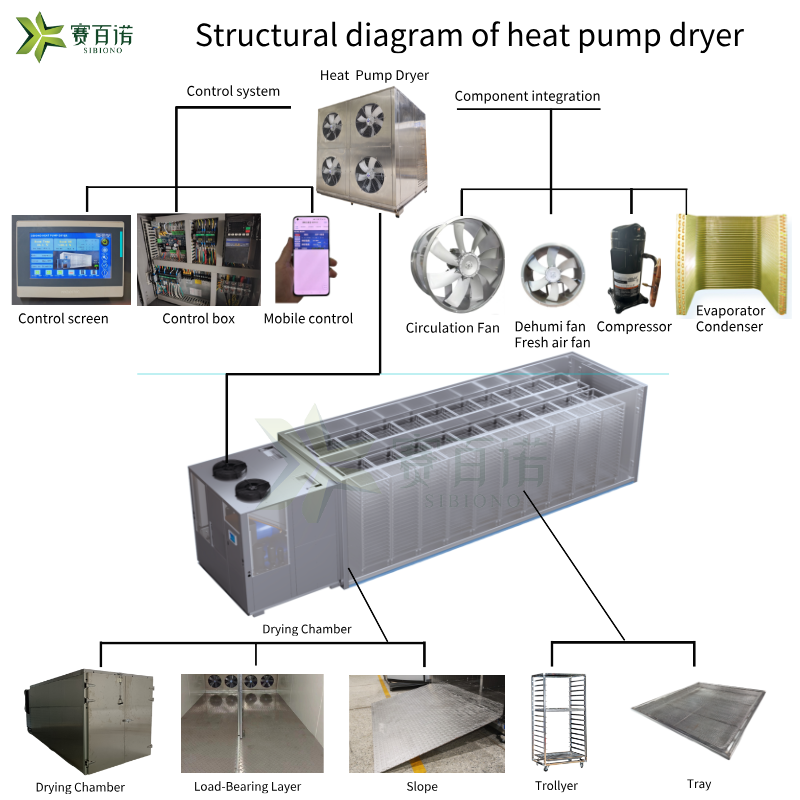

A heat pump dryer uses a refrigerant cycle to provide gentle, dehumidified warmth, perfectly mimicking ideal air-drying conditions on an industrial scale.

-

Precision Humidity & Temperature Control: This is the key advantage. Heat pump dryers actively remove moisture from the air, preventing the high humidity that causes color fading (enzymatic browning) and mold growth. The low, consistent temperature preserves volatile aromatic compounds (essential oils) and anthocyanins (pigments).

-

Superior Product Quality: The result is a premium product: vibrant in color (deep reds, pinks), rich in fragrance, and pliable in texture. This quality is essential for commanding high prices in competitive markets like specialty tea and natural cosmetics.

-

Energy Efficiency: By recycling thermal energy, heat pump dryers operate with 50-70% less energy than electric dryers, significantly reducing the cost per kilogram of dried petals.

-

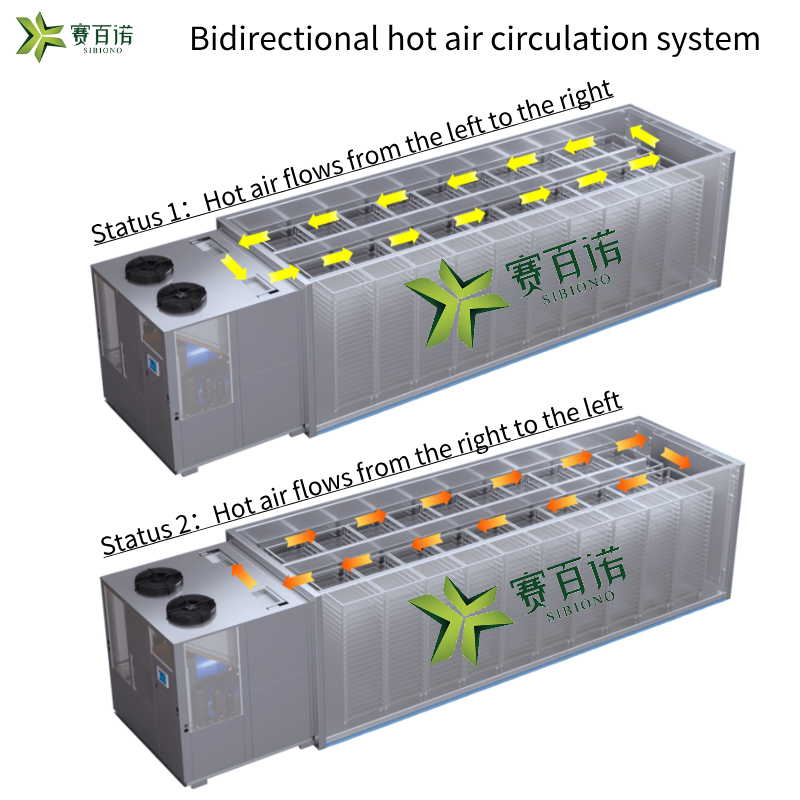

Gentle and Uniform Drying: The even, circulated air ensures every petal in the 1000KG batch dries consistently, eliminating spoilage and waste.

Electric Heating Dryer: The Risky, Low-Quality Alternative

Electric dryers use resistive heating elements that generate intense, dry heat, which is fundamentally unsuitable for delicate flowers.

-

Destructive to Quality: The dry, radiant heat rapidly destroys the petals’ delicate cellular structure. This leads to:

-

Severe Color Loss: High temperatures cause rapid oxidation and degradation of pigments, turning vibrant petals into dull, brownish, and unattractive products.

-

Loss of Fragrance: The volatile essential oils that give roses their value evaporate quickly under high heat, resulting in a final product with little to no scent.

-

Brittle Texture: Petals become brittle and crumble to dust, making them unsuitable for whole-petal applications like tea.

-

-

High Operational Costs: The inefficient conversion of electricity to direct heat leads to high energy consumption, making the process expensive to run.

-

Inconsistent Results: Without proper humidity control, drying is uneven, and the risk of burning or case-hardening is high.

Conclusion: Why a 1000KG Heat Pump Dryer is Essential for Rose Petals

For commercial rose processors, a 1000KG Heat Pump Dryer is not just an equipment choice—it’s a business strategy. It is the only technology capable of preserving the very qualities that make dried rose petals valuable: their color, fragrance, and texture. By ensuring a premium product and reducing energy costs, the heat pump dryer protects profit margins and enhances brand reputation, delivering a definitive return on investment that electric dryers cannot match.