Drying and Processing of 2000KG Apricots: Maximizing Quality and Efficiency

Introduction

For large-scale producers, drying apricots is a primary method to extend shelf life, create value-added products, and access global markets. Processing a 2000KG batch requires robust, efficient, and intelligent technology to ensure consistent quality and operational profitability. This guide details the industrial apricot processing workflow and provides a critical comparison between modern Heat Pump Dryers and traditional Electric Heating Dryers.

Industrial Apricot Drying and Processing Workflow

-

Receiving and Sorting: Incoming apricots are sorted based on size, ripeness, and quality. Only firm, ripe fruit with minimal blemishes is selected for premium dried products.

-

Washing and Pitting: Apricots are thoroughly washed in food-grade spray or immersion washers to remove field dirt and residues. They are then pitted, often mechanically, with care to maintain fruit integrity. Halves are the most common form for drying.

-

Pretreatment (Sulfuring or Blanching):

-

Sulfuring: To preserve the vibrant orange color and prevent darkening, apricot halves are often exposed to sulfur dioxide fumes in a controlled environment.

-

Blanching: Alternatively, blanching in hot water or steam helps to soften the skin, set color, and destroy enzymes that cause spoilage.

-

-

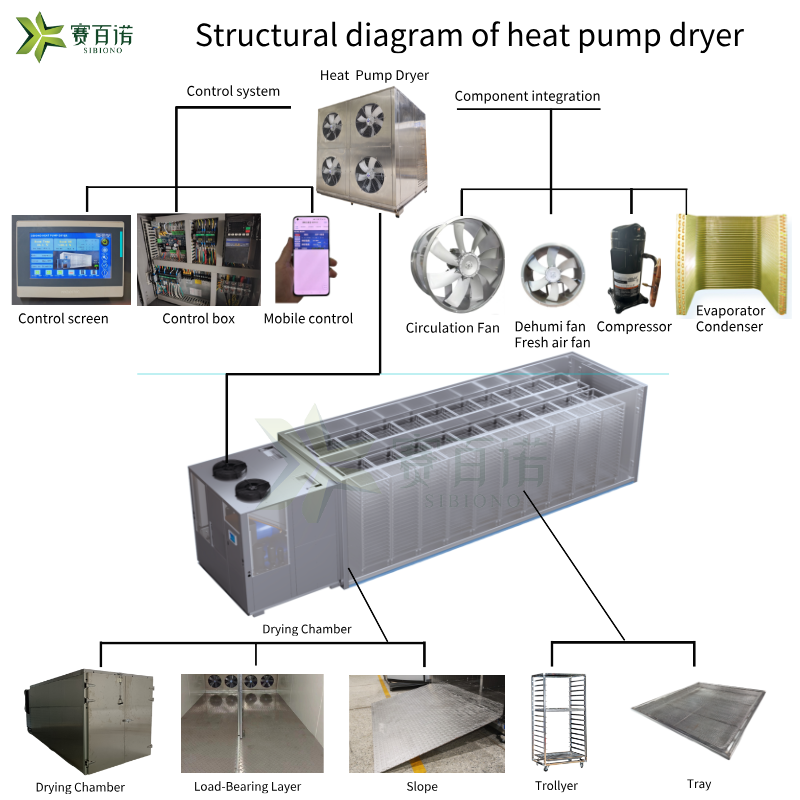

Loading and Drying: Pretreated apricot halves are loaded onto trays in a single layer. They are then dried in the 2000KG capacity dryer. The process is typically done in two stages: an initial higher temperature (e.g., 60-70°C / 140-158°F) to remove surface moisture, followed by a lower temperature (e.g., 50-60°C / 122-140°F) to finish drying evenly without case-hardening.

-

Conditioning and Packaging: After drying to a target moisture content of around 15-20%, the apricots are conditioned. This involves storing them in bins for a period to allow moisture to equalize throughout all batches. Finally, they are packaged for distribution.

Technology Comparison: Heat Pump Dryer vs. Electric Heating Dryer

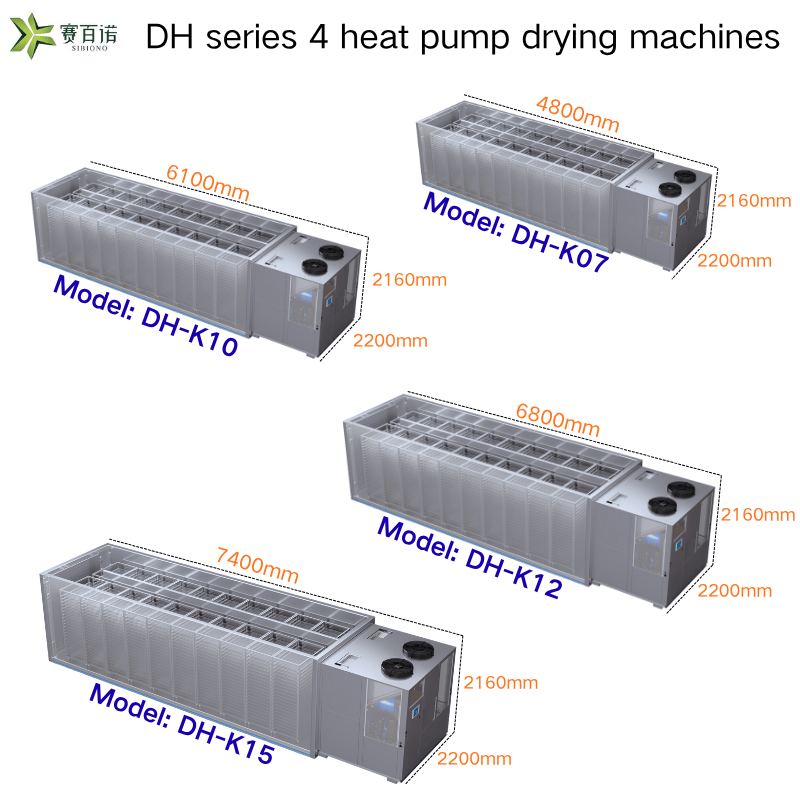

For a 2000KG operation, the choice of drying technology directly impacts the bottom line and product quality.

Heat Pump Dryer: The Advanced Industrial Standard

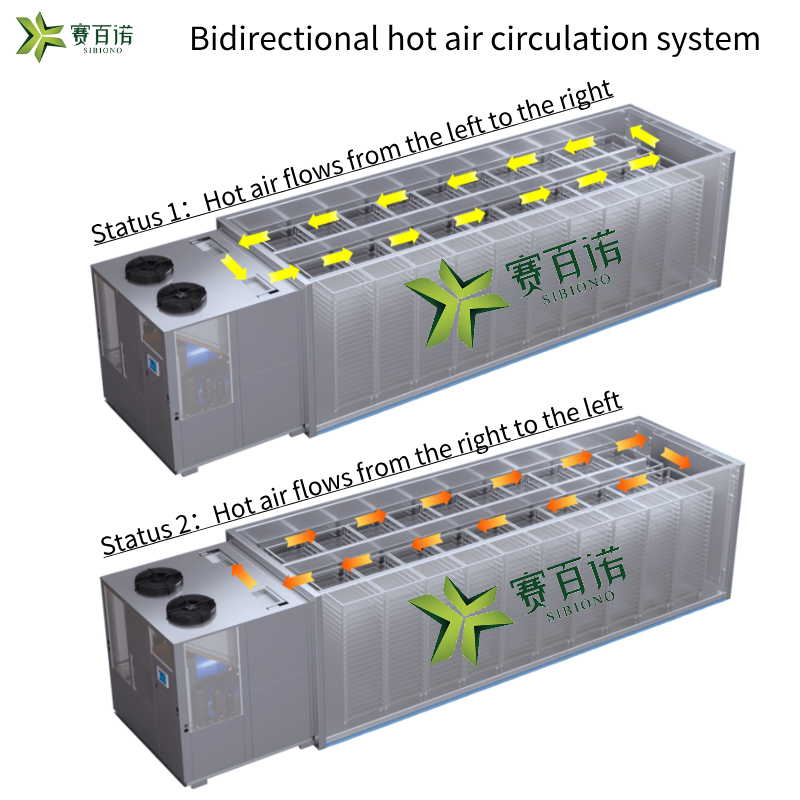

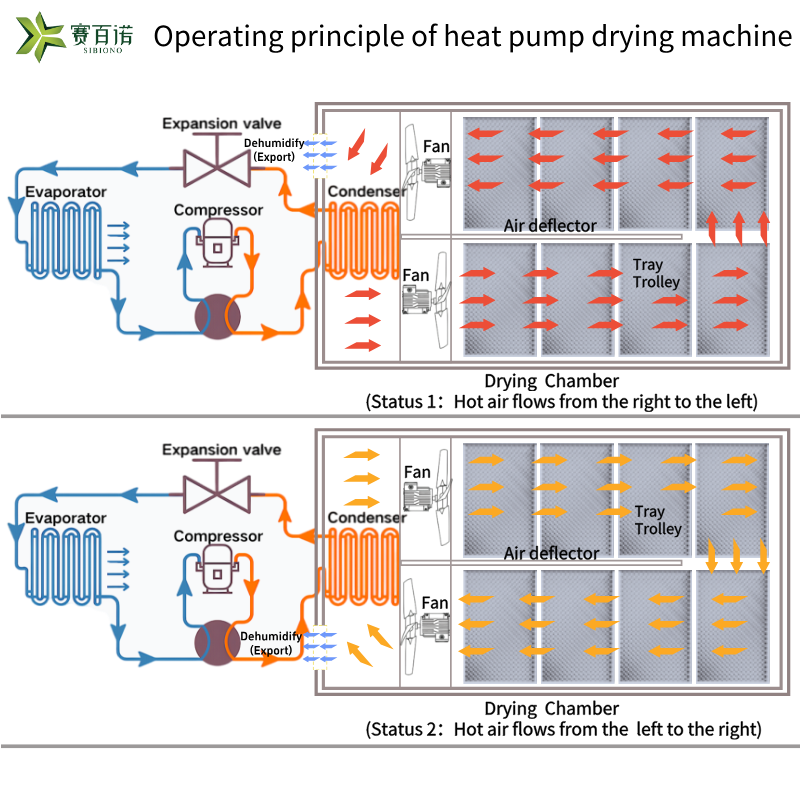

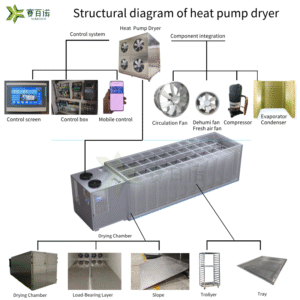

Heat pump dryers use a refrigeration cycle to extract heat from the ambient air and transfer it into the drying chamber, efficiently managing both temperature and humidity.

-

Unmatched Energy Efficiency: By recycling heat, these dryers can achieve energy savings of 60-70% compared to electric dryers. This drastic reduction in electricity consumption makes them the most cost-effective solution for high-volume processing.

-

Superior Product Quality: Precise control over the entire drying environment (temperature and humidity) is critical for delicate fruits like apricots. Heat pump technology prevents “case-hardening” (where the outside hardens and traps moisture inside) and perfectly preserves the fruit’s natural color, chewy texture, rich flavor, and nutritional value.

-

Gentle and Even Drying: The closed-loop system allows for a lower, more consistent temperature, resulting in a uniformly dried product without burnt sugars or off-flavors.

-

Environmental Sustainability: Lower energy consumption translates directly to a reduced carbon footprint, aligning with modern green manufacturing standards.

Electric Heating Dryer: The Conventional, Costly Method

Electric dryers generate heat directly through electrical resistance elements, similar to a large industrial oven.

-

Prohibitively High Operating Costs: The direct conversion of electricity to heat is inherently inefficient for large-scale dehydration. Running a 2000KG electric dryer leads to exorbitant energy bills, severely impacting profitability.

-

High Risk of Quality Issues: Electric dryers often lack sophisticated humidity control. This can lead to uneven drying, case-hardening, and scorching of the natural fruit sugars, resulting in a darker, less appealing product with a caramelized or burnt taste.

-

Simplicity and Lower Initial Investment: The primary advantage is a simpler mechanical system and a potentially lower purchase price. However, this is overwhelmingly negated by long-term operational expenses and inferior product quality.

Conclusion: Why a 2000KG Heat Pump Dryer is Essential for Apricots

For any commercial operation targeting the premium dried fruit market with a 2000KG capacity, the Heat Pump Dryer is the undisputed optimal choice. It transforms a high-energy-cost operation into an efficient, profitable process. The superior ability to preserve the apricot’s golden color, sweet flavor, and soft texture ensures a final product that meets the highest market standards, maximizing your return on investment and building a reputation for quality.