Industrial-Scale Drying Process for 2500KG Prune Batches

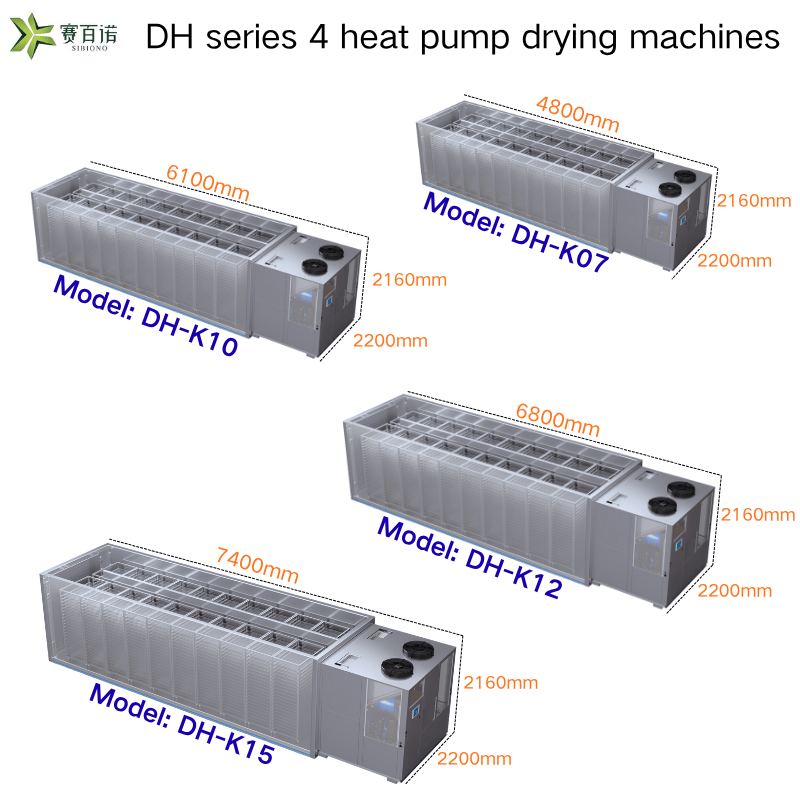

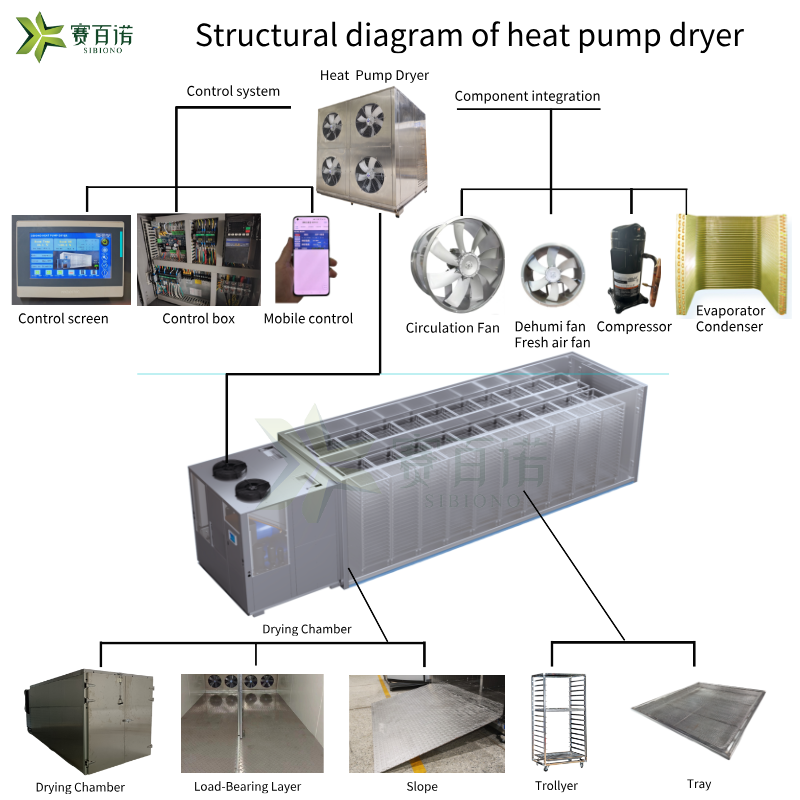

This page details the precision drying cycle for processing 2500KG (2.5 Ton) of fresh plums into premium prunes per batch. Our industrial dryer utilizes a prolonged 50-hour cycle within a 65-75°C range to ensure optimal sugar concentration, desired chewy texture, and maximum shelf life for large-scale commercial operations.

The 50-Hour Precision Drying Cycle for 2500KG Prune Batches

This extended, gentle process is critical for developing the complex flavors and proper texture of high-quality prunes without case-hardening.

-

Phase 1: Gentle Wilting & Moisture Equalization (65°C – 68°C | Hours 1-18)

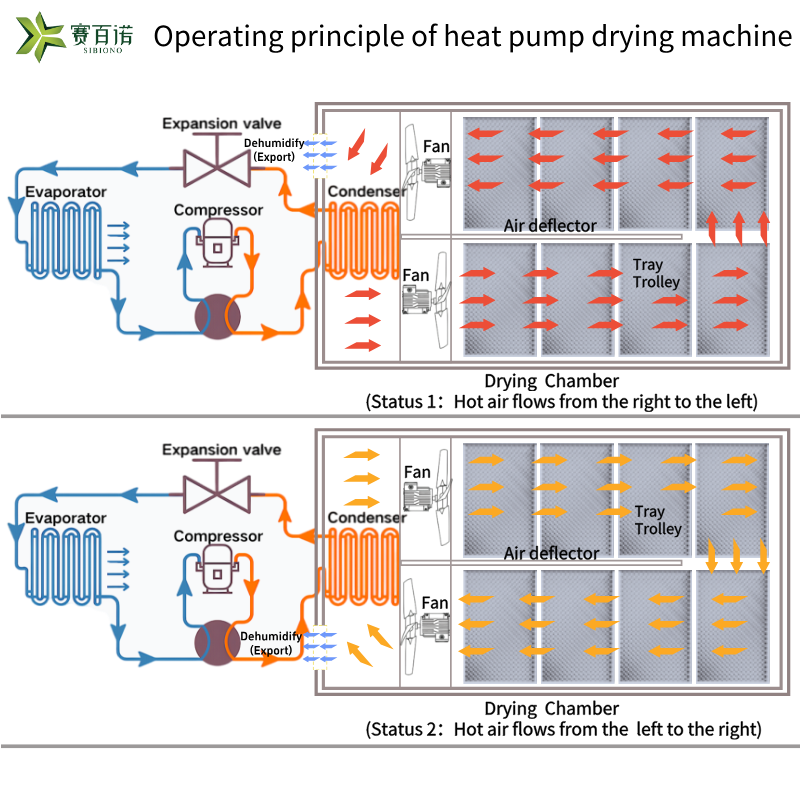

The cycle begins at the lower end of the temperature spectrum. This extended initial phase allows for the gentle wilting of the plums and the slow, even migration of internal moisture to the surface. Consistent, horizontal airflow across all 2500KG of product is vital here to prevent uneven drying and prepare the fruit for the next stage. -

Phase 2: Active Dehydration & Sugar Concentration (68°C – 72°C | Hours 19-40)

The temperature is gradually increased to actively remove the bulk of the moisture. The prolonged exposure to this moderate heat allows for the natural sugars in the fruit to concentrate, developing the characteristic rich, sweet flavor of a premium prune. This slow process ensures the skin remains permeable, allowing internal moisture to escape without trapping it inside. -

Phase 3: Final Moisture Balancing & Pasteurization (72°C – 75°C | Hours 41-50)

In the final stage, the temperature is elevated to its peak. This ensures the entire batch reaches the target, uniform moisture content (typically around 18-21%) essential for a perfect chewy texture and shelf stability. This phase also acts as a critical pasteurization step, eliminating any potential spoilage microorganisms and ensuring the final prune product is safe for consumption and has an extended shelf life.

Key Benefits of Our 2500KG Prune Dryer:

-

Unmatched Batch Capacity: Process 2.5 metric tons of plums in a single batch, designed for the largest processing facilities.

-

Superior Product Quality: The 50-hour, low-temperature profile is engineered to produce prunes with superior color, flavor, and texture compared to faster, high-heat methods.

-

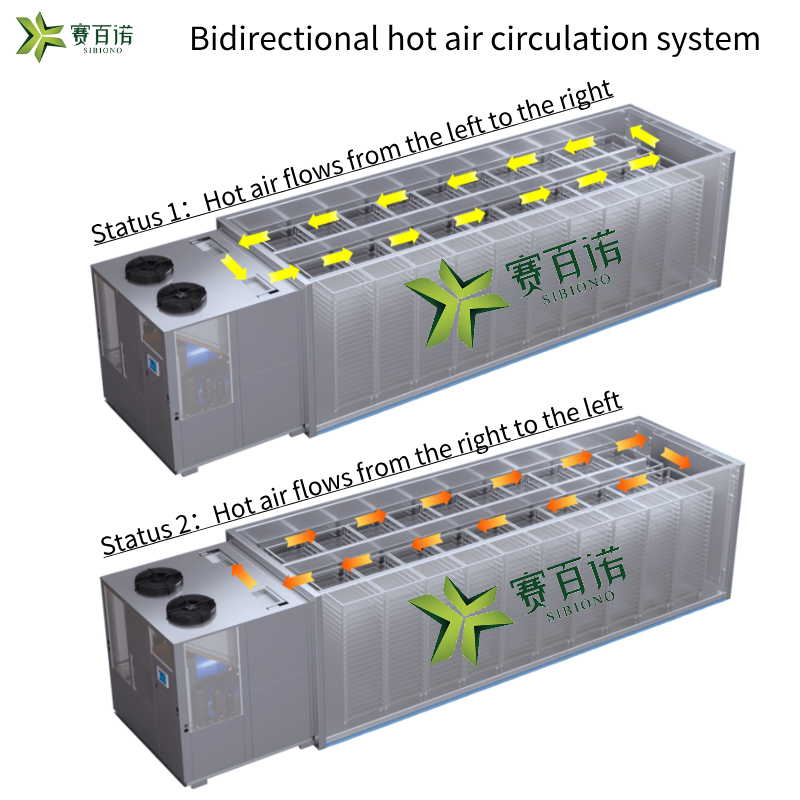

Guaranteed Uniformity: Advanced airflow technology ensures every plum, regardless of its location in the 2500KG load, dries at the same rate.

-

Enhanced Food Safety: The integrated high-temperature finishing phase guarantees a microbiologically safe product that meets global food safety standards.

-

Energy Optimization: Despite the long cycle, our dryers are built with heat recovery systems to minimize overall energy consumption per kilo of finished product.

Industries and Applications:

This industrial dryer is the ideal solution for producers of:

-

Pitted and Whole Prunes

-

Prune Juice Concentrate (for drying before further processing)

-

Private Label and Bulk Ingredient Prunes

Ready to Scale Your Prune Production?

If you require a high-capacity, reliable drying solution for your prune operation, our 2500KG/batch industrial dryer is built for your needs. Contact us today for a detailed quotation and performance data.