High-Quality Industrial Drying Process for 1000KG Batches of Bananas

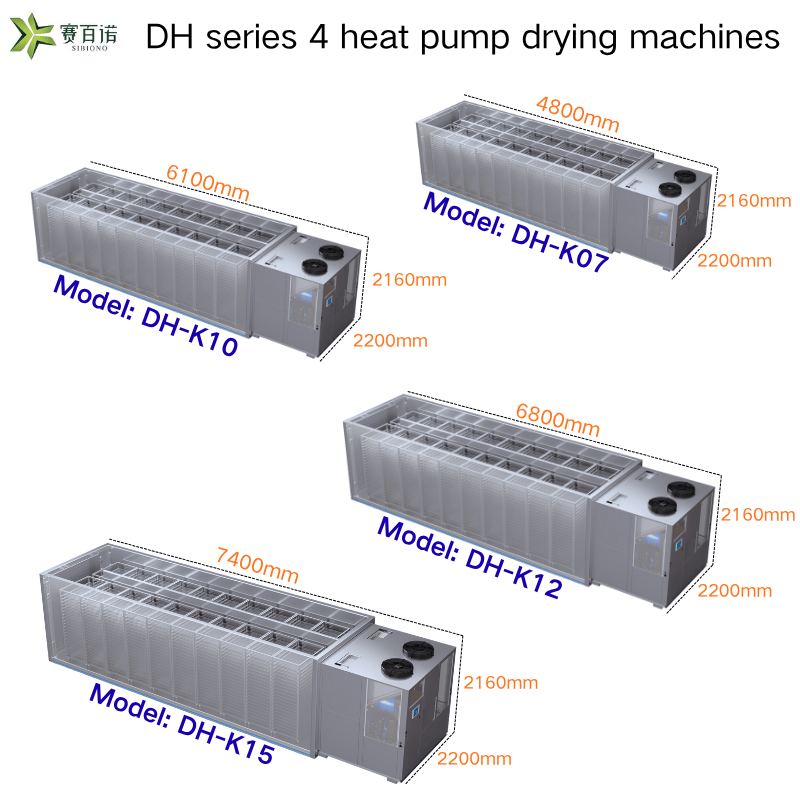

This page details our precision industrial drying process designed for high-volume banana processing. Our dryer handles 1000KG of bananas per batch, transforming them into uniformly dried banana chips or banana pieces through an 11-hour, low-temperature cycle. This method is engineered to preserve natural color, sweetness, and nutritional value while achieving a long shelf life.

The 11-Hour, Gentle Drying Cycle for 1000KG Banana Batches

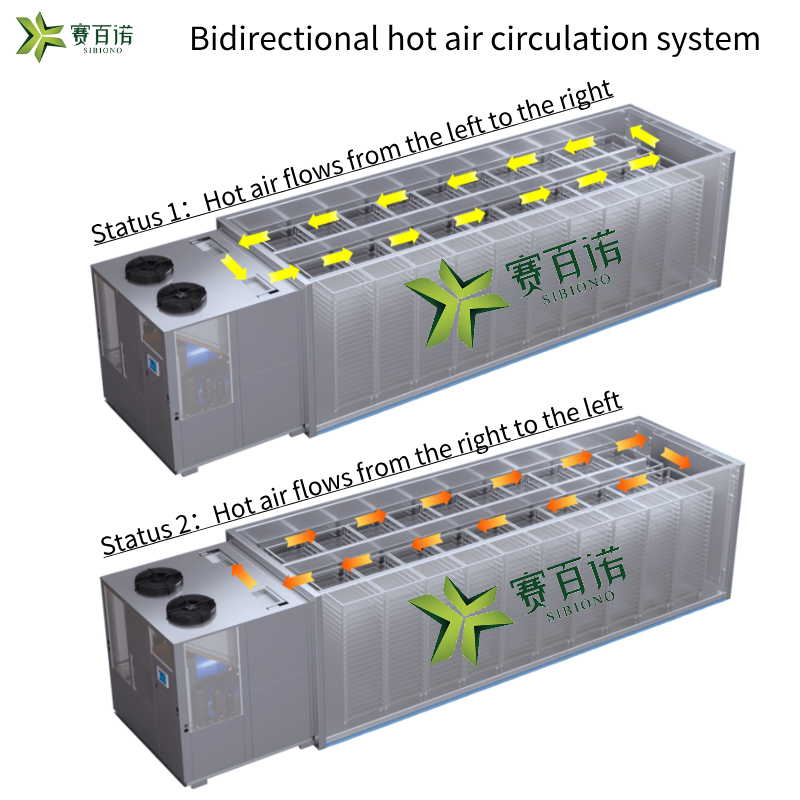

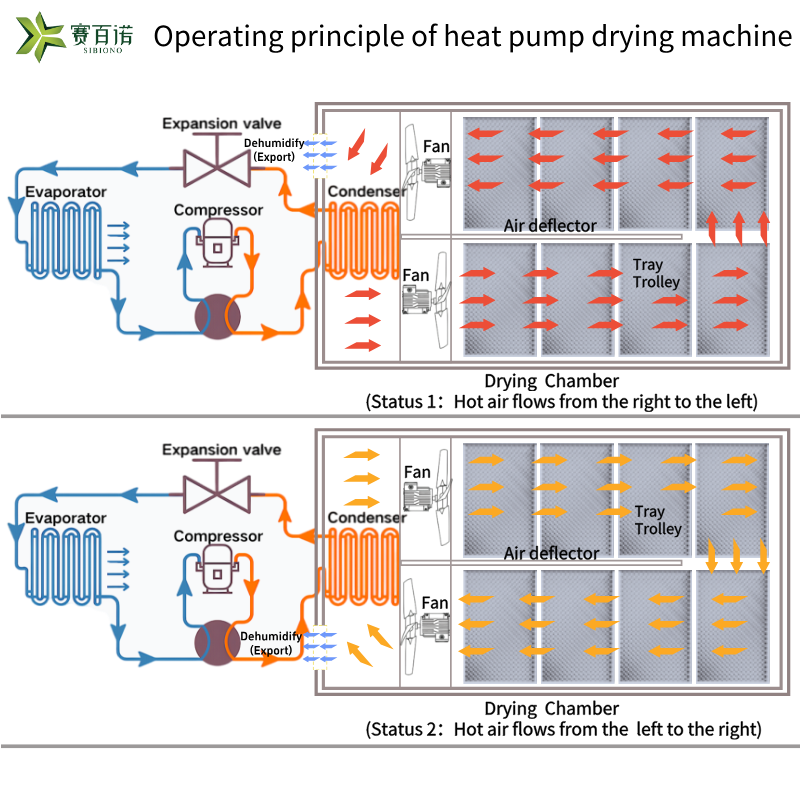

Our patented airflow and temperature control system ensures perfect results from the top to the bottom of the chamber for all 1000 kilograms.

-

Phase 1: Controlled Moisture Removal (55°C – 60°C | Hours 1-4)

The process begins at a moderate temperature to slowly and evenly remove moisture without case-hardening the exterior. This gentle start is critical for bananas, as it prevents the sugar from caramelizing on the surface too early, which would lead to dark, uneven color and a tough texture. Consistent airflow across all trays ensures every slice dries uniformly. -

Phase 2: Core Drying Phase (60°C – 65°C | Hours 5-9)

The temperature is gradually increased to actively drive out the majority of the internal moisture. This extended phase at a stable heat level allows the banana pieces to dry from the inside out, maintaining their desired texture—whether chewy or crisp. The controlled environment prevents overheating, which can destroy nutrients and flavor. -

Phase 3: Finishing & Pasteurization (65°C – 68°C | Final 2 Hours)

In the final stage, the temperature is raised to the peak range. This serves two key purposes: it completes the drying process to the target moisture content, ensuring a crisp or leathery texture as desired, and it acts as a pasteurization step. This heat treatment eliminates microorganisms, ensuring the final dried banana product is microbiologically safe and has an extended shelf life for global distribution.

Key Benefits of Our 1000KG Banana Dryer:

-

Unmatched Capacity: Process 1000KG (1 Ton) of bananas in a single, efficient batch, maximizing your production output.

-

Premium Product Quality: The gentle temperature ramp preserves the banana’s natural golden color, sweet flavor, and vital nutrients far better than high-temperature methods.

-

Complete Process Control: Precision digital controls for temperature and time allow for consistent, repeatable results batch after batch.

-

Built for Food Safety: The integrated pasteurization phase in the cycle guarantees a safe, shelf-stable product that meets international food safety standards.

-

Energy Efficient Design: Advanced thermal efficiency and heat recovery systems make this large-scale drying process remarkably cost-effective to operate.

H2: Ideal for Large-Scale Banana Chip and Dried Banana Production

This industrial dryer is the perfect solution for manufacturers producing:

-

Dried Banana Chips (Crispy or Chewy)

-

Banana Powder / Flour

-

Sliced Dried Bananas for Cereals and Snacks

Ready to Optimize Your Banana Drying Operation?

If you are looking for a reliable, high-capacity drying solution for your banana products, our 1000KG/batch industrial dryer is the answer. Contact us today for a detailed quotation and a full technical data sheet.