The Ultimate Guide to Drying 1000kg of Apple Slices with a Heat Pump Dryer

For commercial producers of dried fruits, efficiently processing large volumes like 1000kg of fresh apple slices is a core business challenge. The choice of drying technology directly impacts product quality, throughput, and most importantly, operational costs. While traditional methods like electric or gas-fired dehydrators exist, the heat pump dryer has emerged as the gold standard for energy-efficient and high-quality commercial drying.

This article provides a detailed walkthrough of drying 1000kg of apple slices using an industrial heat pump dryer, including a precise analysis of the running (energy cost).

Why Choose a Heat Pump Dryer for Your Apple Drying Business?

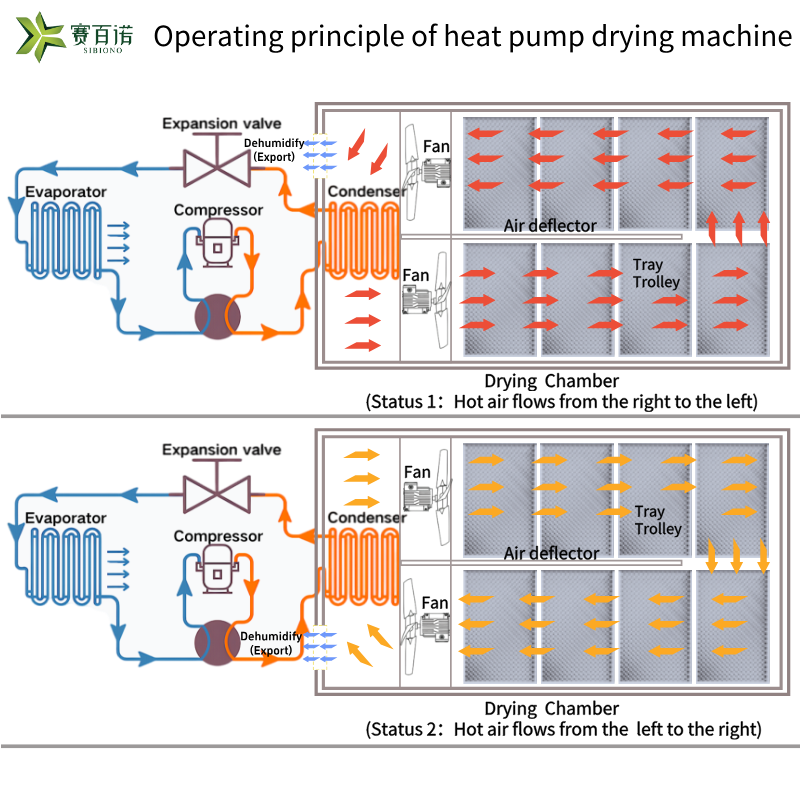

A heat pump dryer is not just a simple fruit dryer; it’s a sophisticated system that recycles heat. Unlike conventional dehydration equipment that generates heat, a heat pump extracts ambient heat from the air and intensifies it in a closed loop. This process offers key advantages:

-

High Energy Efficiency: It can use 1 unit of electricity to produce 3-4 units of heat, slashing energy consumption by up to 60-70% compared to electric heating.

-

Superior Product Quality: It operates at lower temperatures (typically 40-65°C), which preserves the apple’s natural color, nutrients, and shape without case-hardening.

-

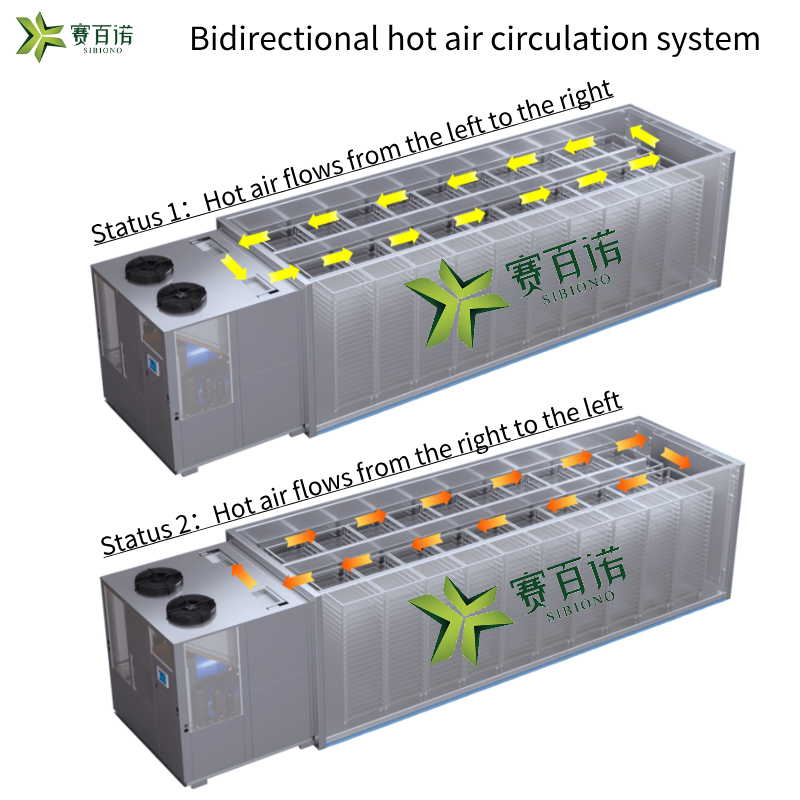

Consistent and Even Drying: Precise control over temperature and humidity ensures every batch of apple chips is uniformly dried.

-

Environmentally Friendly: With lower energy consumption, it has a smaller carbon footprint.

The Step-by-Step Process for 1000kg of Apple Slices

Step 1: Preparation (Washing, Coring, Slicing)

Before loading the apple dryer, fresh apples are washed, cored, and uniformly sliced to a thickness of 5-8mm. Uniform thickness is critical for consistent drying.

Step 2: Loading the Drying Trays

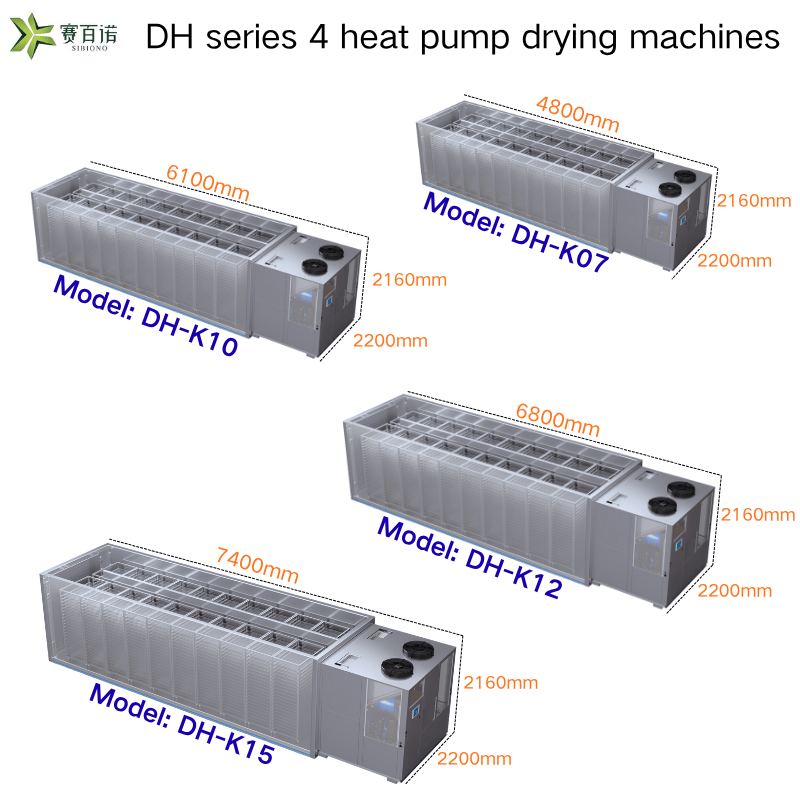

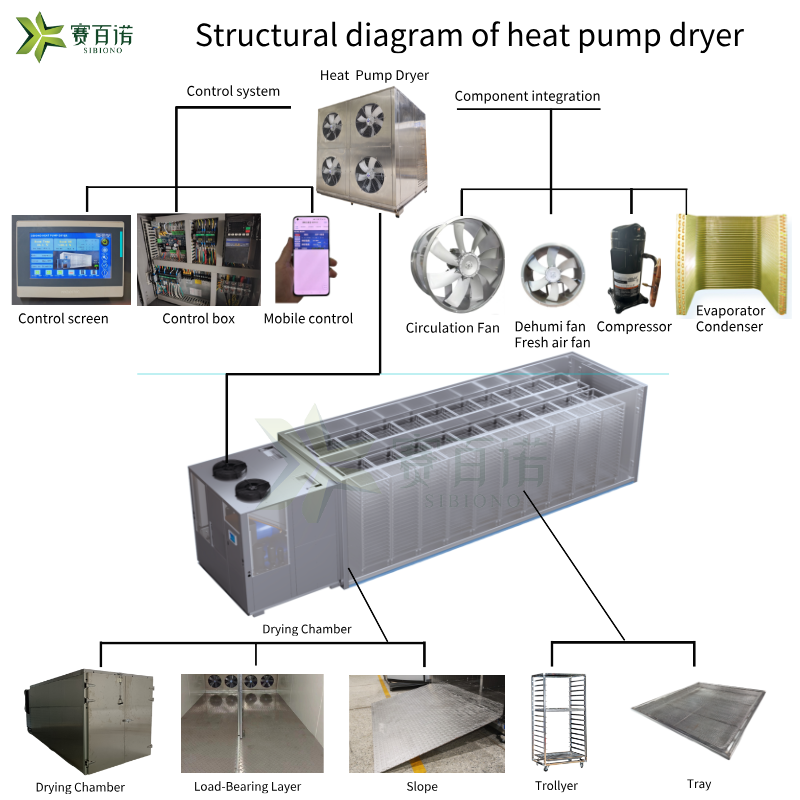

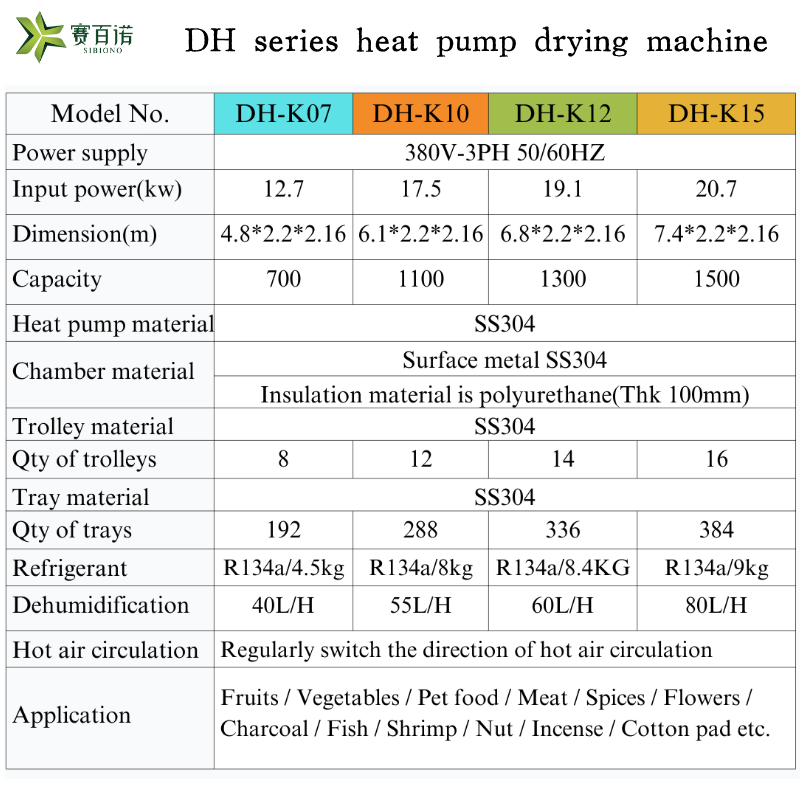

The apple slices are evenly spread on stainless steel trays. An industrial heat pump dryer with a 1000kg capacity typically has a large drying chamber that can accommodate dozens of these trays on sturdy trolleys.

Step 3: The Drying Cycle

This is where the heat pump drying machine shines. The operator sets the optimal parameters:

-

Temperature: 55-60°C (131-140°F)

-

Humidity: Controlled and automatically dehumidified by the system.

-

Time: Approximately 8-10 hours.

The dryer circulates warm, dry air across the trays, gently removing moisture. The system continuously recycles the heat from the exhaust air, making the process incredibly efficient.

Step 4: Cooling and Packaging

Once the drying cycle is complete and the moisture content has dropped from ~85% to below 10%, the apple chips are cooled to room temperature before being packaged to prevent condensation and ensure crispness.

Running Energy Cost Analysis for 1000kg of Apple Slices

This is the most critical section for any business owner. Let’s calculate the operational cost based on the heat pump dryer’s efficiency.

Assumptions:

-

Fresh Apple Weight: 1000 kg

-

Final Dried Weight: ~120-150 kg (an 85-88% reduction)

-

Heat Pump Dryer Power: 300-350 kWh/batch

-

Average Electricity Cost: $0.15 per kWh

Calculation:

-

Total Energy Consumed: 300 kWh

-

Total Energy Cost: 300kWh * $0.15/kWh = $45

Result: The estimated energy cost to dry 1000kg of fresh apple slices into high-quality apple chips is approximately $45 per batch.

Conclusion: A Smart Investment for Your Business

Investing in an industrial heat pump dryer is a strategic decision for any serious fruit dehydration business. For a remarkably low energy cost of around $20, you can transform 1000kg of fresh apples into a valuable, shelf-stable product with exceptional quality and color retention.

When searching for the right equipment, whether you call it a heat pump dryer, fruit dryer, apple dryer, or dehydrator, prioritize units designed for commercial-scale operation with robust humidity control and energy-saving features. The long-term savings and superior product output will ensure a rapid return on investment.