Industrial Mango Drying System – 500KG Per Batch Processing

Producing high-quality dried mango slices for the commercial market requires precision, hygiene, and efficiency. While traditional sun-drying is unpredictable, modern industrial heat pump dryer for mango offers a controlled, energy-efficient solution. This article provides a detailed walkthrough of the mango drying process, with a special focus on the advanced drying technology of a 500kg mango dryer and its operational costs.

The Mango Drying Preparation Process

Before drying begins, raw mangoes must be carefully prepared to ensure a premium final product.

-

Selection & Sorting: Only ripe, firm, and blemish-free mangoes are selected. Uniform ripeness is crucial for consistent drying.

-

Washing & Peeling: Mangoes are thoroughly washed in food-grade sanitizers to remove dirt and contaminants. The skin is then peeled off.

-

Slicing & Pretreatment: Mangoes are sliced into uniform pieces, typically 8-12 mm thick. To preserve their vibrant color and prevent browning, slices are often dipped in a solution of ascorbic acid (vitamin C) or potassium metabisulfite.

-

Loading the Drying Trays: The pretreated slices are evenly spread on stainless steel trays. Proper spacing is vital for consistent air circulation.

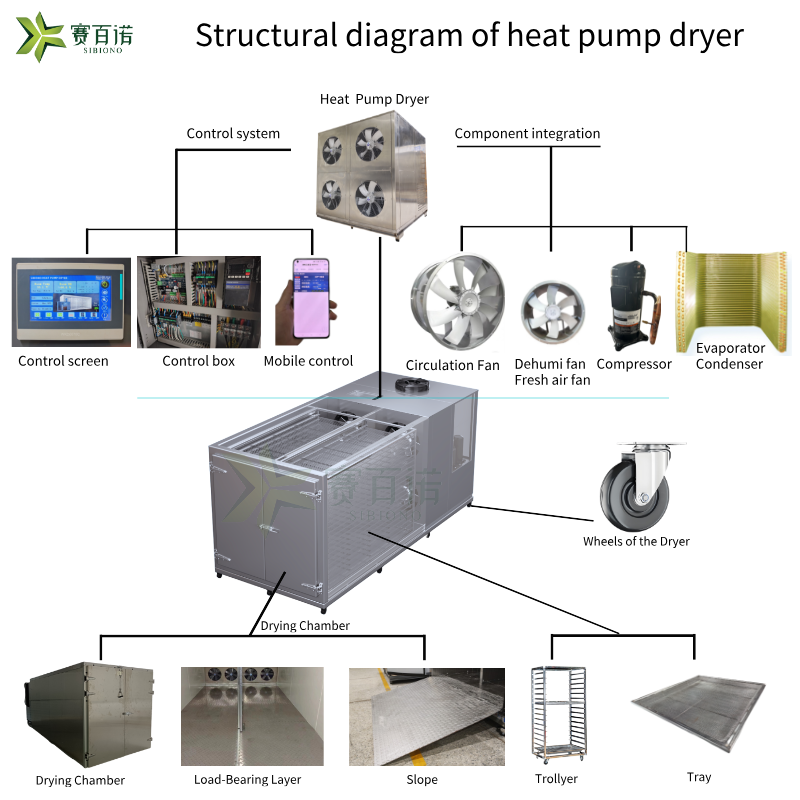

The Heart of the Operation: Heat Pump Drying Technology

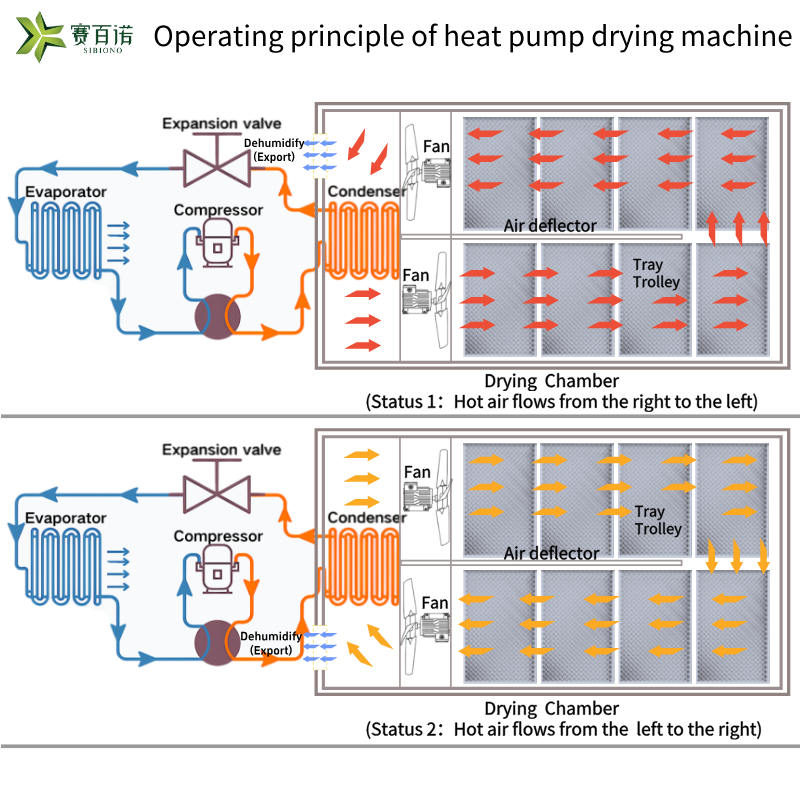

This is where the mango drying heat pump machine transforms the process. Unlike traditional methods that use direct high heat, a heat pump dryer works by transferring latent heat from the surrounding air into the drying chamber. It’s a closed-loop system that dehumidifies and reheats the air, making it incredibly efficient.

For a 500kg capacity industrial mango dryer, the process is meticulously controlled in stages:

Stage 1: Initial High-Humidity Drying

-

Temperature: 65°C – 70°C (113°F – 122°F)

-

Duration: 3-5 hours

-

Process: In this stage, the mango slices have a very high moisture content (around 80-85%). The dryer uses high temperature and high airflow to remove surface moisture, causing surface hardening and stabilizing the color of dried mango (forming a hard shell that prevents oxidation).

Stage 2: Constant Rate Drying

-

Temperature: 55°C – 60°C (131°F – 140°F)

-

Duration: 8-12 hours

-

Process: This is the main drying phase where the bulk of the moisture is removed. The heat pump maintains a constant, moderate temperature, efficiently pulling moisture out of the mango slices. The built-in dehumidifier actively removes water vapor from the air, maintaining a low humidity level inside the chamber.

Stage 3: Final Falling Rate Drying / Conditioning

-

Temperature: 50°C – 55°C (122°F – 131°F)

-

Duration: 3-5 hours

-

Process: As the mango slices near the target moisture content (typically 12-15%), the rate of drying slows down. The temperature is slightly reduced to avoid scorching and to ensure the final product has the perfect chewy texture and does not become brittle.

Total Drying Time: Approximately 14 to 21 hours for a full batch, depending on mango variety, slice thickness, temperature, and initial moisture content.

Key Advantages of Using a 500kg Heat Pump Dryer for Mango

-

Superior Product Quality: Low-temperature drying preserves the natural color, flavor, vitamins, and aroma of the mango.

-

Hygienic & Contamination-Free: A fully enclosed system protects the product from dust, insects, and microbes.

-

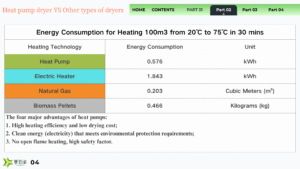

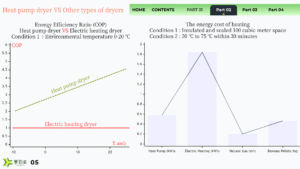

Energy Efficiency: This is the most critical benefit, which we will explore in detail below.

Running Cost Analysis: Electricity Consumption of a 500kg Mango Dryer

One of the most common questions from commercial producers is about operational costs. The 500kg batch mango dryer running cost is significantly lower than traditional electric or fuel-fired dryers.

A standard 500kg heat pump dryer has an average power rating of 15-20 kW. This power is used to run the compressor, fans, and control system.

Calculating Energy Consumption per Batch:

Let’s assume a conservative average power consumption of 18 kW and a total drying cycle of 16 hours.

-

Total Energy Used per Batch = Power (kW) × Time (hours)

-

Total Energy Used per Batch = 18 kW × 16 hrs = 288 kWh

Estimating Cost:

The cost will depend on your local industrial electricity tariff. Assuming an average rate of $0.15 per kWh:

-

Total Electricity Cost per Batch = 288 kWh × $0.15/kWh = $43.2

This means it costs approximately $43.2 to dry 500kg of fresh mango into about 100kg of dried product. This high efficiency is achieved because the heat pump moves heat rather than generating it directly, often delivering a Coefficient of Performance (COP) of 3-4, meaning it moves 3-4 times more energy than it consumes.

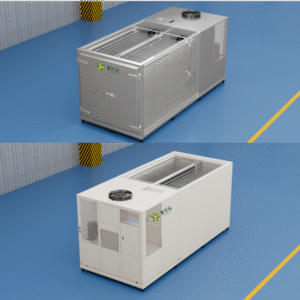

DH-K15 machine installation effect and parameter table

Investing in a large capacity mango drying equipment like a 500kg heat pump dryer is a strategic move for any serious commercial producer. It ensures consistent, high-quality dried mango that meets international food safety standards, all while keeping energy costs manageable. By understanding the precise drying stages and the realistic energy consumption for mango processing, businesses can accurately forecast production costs and improve their profitability in the competitive dried fruit market.

|

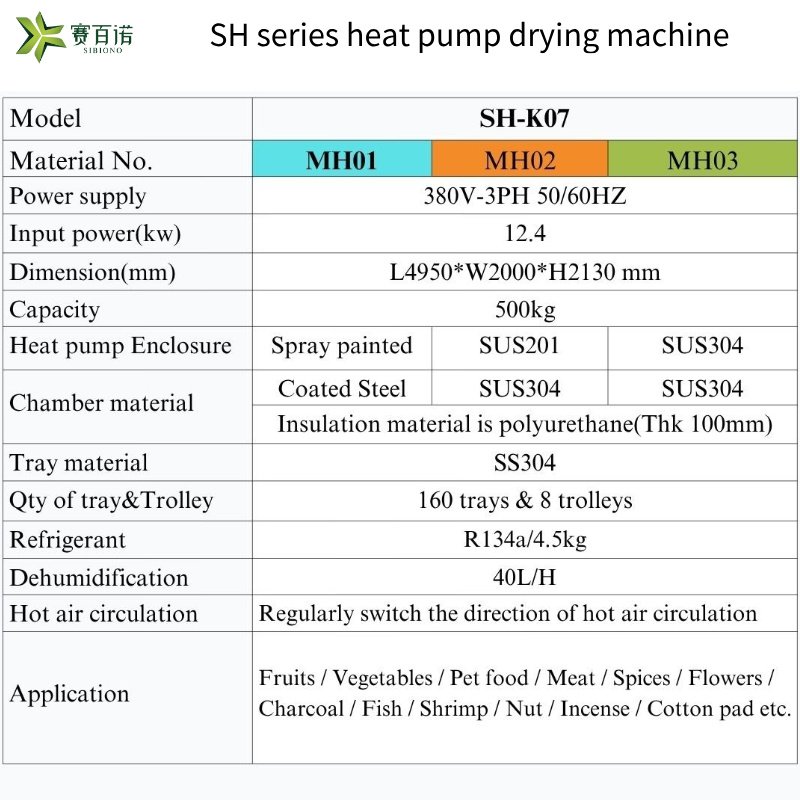

Specification of SH-K07 |

||||

|

Model |

SH-K07 | SH-K07 | SH-K07 | |

|

Material No. |

MH01 | MH02 | MH03 | |

| Power input(including fan) | KW |

12.4 |

||

| power supply | V/PH/HZ |

380V-3PH 50/60HZ |

||

| Max dehumidity | L/H |

40 |

||

| Input capacity | KG/batch |

500-700 |

||

| Dimensions | mm |

L4950*W2000*H2130 |

||

| Qty of trolley | unit |

8 |

||

| Qty of tray | Pieces |

160 |

||

| Heat pump Enclosure material | / | Spray painted | SUS201 | SUS304 |

| Chamber material | / | Coated Steel | SUS304 | SUS304 |

| Tray material | / | SUS304 | SUS304 | SUS304 |

| Trolley material | / | SUS201 | SUS304 | SUS304 |

| Functions |

Heat dry, Cool dry, Dehumidify |

|||

| Blowing type |

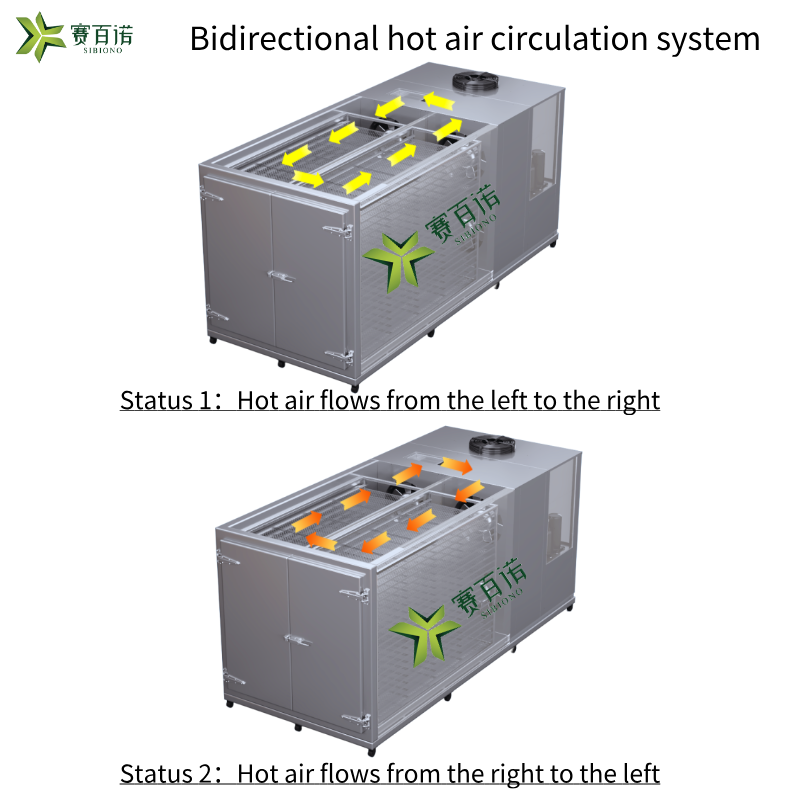

Horizontal wind + Bidirectional hot air circulation |

|||

| Installation method |

No need to install, just connect to the power supply upon arrival and it can be used |

|||

Conclusion: A Smart Investment for Scale

Investing in a large capacity mango drying equipment like a 500kg heat pump dryer is a strategic move for any serious commercial producer. It ensures consistent, high-quality dried mango that meets international food safety standards, all while keeping energy costs manageable. By understanding the precise drying stages and the realistic energy consumption for mango processing, businesses can accurately forecast production costs and improve their profitability in the competitive dried fruit market.

Keywords Integrated: mango drying process, heat pump dryer for mango, 500kg mango dryer, commercial mango drying, industrial mango dryer, mango drying stages, energy consumption mango dryer, 500kg batch running cost, mango dehydration technology, large capacity mango drying equipment.

-3-300x225.jpg)